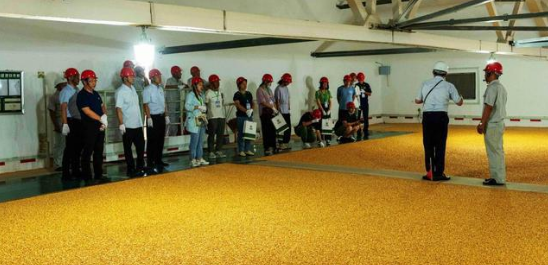

During the open day of SINOGRAIN’s Shanxi Branch, the public see a clean, tidy and modern granary with appropriate temperature.

Picture taken by Zhou Yan

Source: China Daily

COVID-19 epidemichas made the public pay great attention to food security. On October 18, 2020, Shanxi Branch of SINOGRAIN held the third open day for the public to visit China grain storage with the theme of "Technology Eempowerment, Cherishing and Saving Grains,". Representatives from all walks of life were able to visit the warehouse and learn about how to store grain scientifically and safely.

In the Shanxi Directly-managed Grain Depot of SINOGRAIN, the public saw that every link in the whole process was mechanized and automatic, including the registration, sampling, testing, weighing and purchase, settlement by the supervisor and unified payment.

It was learnt that the purchase system of "all-in-one card" was used in thepurchase of national subsidized grains. The whole process of national subsidized grain was driven by IT technology and was traceable, including the purchase, warehousing and sales, and thus truly realizing theopenness, transparency and traceability in the grain purchase process.

However, there was much more knowledge to be explored.

After the detection of near-infrared grain moisture analyzer, the data of bulk density, protein and extensibility of two different varieties of wheat were clearly shown on the instrument screen. “These data will become a basis for selecting grains to be stored." According tothelocal staff ofthe ShanxiDirectly-managed Grain Depot of SINOGRAIN, the grains needed to go through toxicity inspection for the first time. When there served grains reached one-third and one-half of thestoragecapacity of the warehouse, the toxicity inspection would be conducted again. Repeated inspection could help select grains carefully and ensure the quality and safety of grains.

The selected grains then would be sent to the warehouse equipped with scientific and technological management tools and devices. "The warehouse is controlled by the technology of internal circulation storage. Therefore, the temperature in summer is 23 degrees Celsius and the humidity is below 40%, so that the grains will not deteriorate." According tothe local staff ofthe ShanxiDirectly-managed Grain Depot of SINOGRAIN, based on the climate in the northernpart ofChina, this technology used the ventilation in the winter and stored the cold air in the corresponding part of the grain pile. In summer, the cold air in the grain pileis drawn out by the circulation fan, andis transported to the warehouse. Then, the cold air passes through the grain pile and then enters the air duct, and circulates repeatedly. In this way, an internal circulationis formed to reduce the surface temperature of the grain pile and the humidity in the warehouse, and curbs the growth of grain pests. In this way, green, scientific and technological, and safe grain storagewould berealized.

This technology is also a good example of SINOGRAIN’s technological innovation in grain storage. Based on safe grain storage, green grain storage, energy saving and consumption reduction, and IT and intelligent technologies, SINOGRAIN basically forms the storage technology systems, i.e., low temperature and quasi-low temperature in the northern part ofChina, and temperature control and controlled atmosphere storage in the southern part ofChina. In the SINOGRAIN, 98% of national grain reserves was applied with green storage technology, and the comprehensive loss rate during the storage period was controlled to less than 1%.

Technological innovation improved the management and protection level of the granary and greatly increased the amount of grain reserves. According to the reporter, thegranary with a flat surface could store more than 7,000 tons of wheat. However, only a few personnel were needed. With the help of an intelligent management system platform, hundreds of temperature sensors and high-definition cameras, the staff in the granary with a flat surface could efficiently manage and monitor the warehouse in real time.

"A warehouse with the storage capacity of more than 7,000 tons of wheat and a depth of 5.8 meters is divided into four layers. Each layer is divided into six rows, and 15 data monitoring points are setin everyrow. Therefore, a comprehensive monitoring system can be formed for grain situation." According to the local staff ofthe ShanxiDirectly-managed Grain Depot of SINOGRAIN, the online grain situation monitoring system could provide information about the grain storage in any warehouse of any branchoftheSINOGRAIN, and then conduct big data analysis to predict and warn the changes of grains intelligently .

With the development of science and technology,theSINORGAIN no longer needed to rely solely on reports. Instead, it could directly grasp and control the grain situation in time, so that grains could be visible,wellmanaged, andwellstored.

Since 2018,the SINOGRAIN successfully held open day activities for two times. 2020 marked the 20th anniversary of the founding of SINOGRAIN. For the celebration of its 20th anniversary,theSINOGRAIN gave the public access to nearly 140grain depots online and offline, and 30 provincial-lelvel depots. Thesedepotsallowed the public to learn about all reserve management links of grains, cotton, oils and other reserves, such aspurchasing, storage, transportation andR&D.

SOURCE:http://www.farmer.com.cn/2020/10/22/99860951.html

Category

Grain Reserve Empowered by Technology- An example of SINOGRAIN's Shanxi Branch

Contributor

Grain Reserve Empowered by Technology- An example of SINOGRAIN's Shanxi Branch

Country

Technical Solution