Ⅰ. Overview of the Project

Ar Horqin Banner falls under the jurisdiction of Chifeng City in the Inner Mongolia Autonomous Region. Located in the east of Inner Mongolia, it was once a nationally registered impoverished county suffering from frequent natural disasters, outmoded infrastructure, and backward industrial development. The sugar industry is a pillar of local agriculture, with sugar-beet acreage reaching 200,000 mu (13,333 hectares). However, reliance on traditional production methods and extensive planting management limited the output and quality of sugar beets from the county, leaving Ar Horqin’s agricultural industry “at the mercy of the climate” for many years.

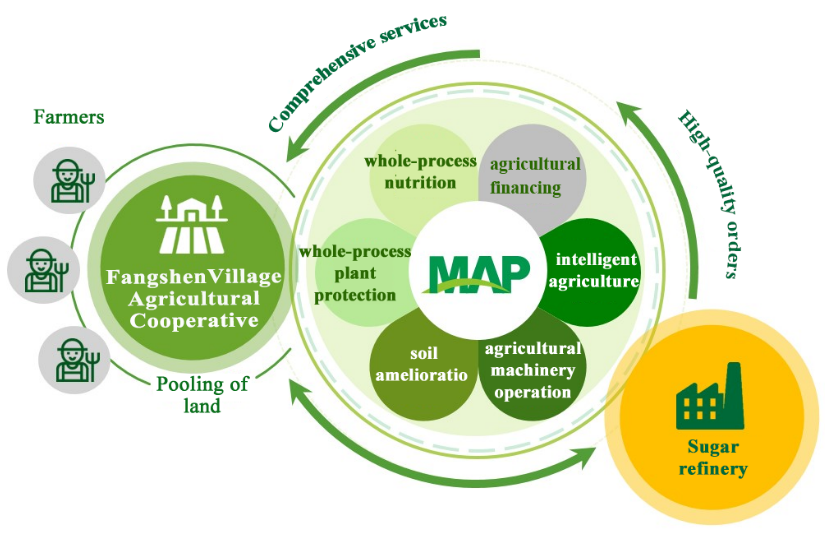

Sinochem Agriculture, a subsidiary of Sinochem Group, officially settled in Ar Horqin in 2018. Following several successful trials, the company built a modern MAP technical service center and a standardized MAP demonstration farm, established a high-quality sugar beet technology promotion team, developed a new model of “government + MAP + farmers’ cooperatives + sugar refinery,” adopted Sinochem MAP modern agricultural end-to-end service solutions, and utilized digital agricultural technology to develop Ar Horqin’s beet industry and help eliminate poverty.

II. Approaches and methodology

● Collaborating with local government to form taskforces

To better advance the core work of poverty alleviation and rural revitalization – and after assessing Ar Horqin’s development needs as well as production pain points – Ar Horqin and Sinochem Agriculture collaborated to set up taskforces in 12 villages of three towns – Tianshan, Shuangsheng and Xianfeng – and drafted a working charter.

The government has taken the initiative to help set up agricultural cooperatives, organizing farmers and unifying their operations. Poor households participate in a farmers’ cooperative through land shares or land transfers.

● Agricultural cooperation with a sugar company

Sinochem MAP cooperates with Ar Horqin Lingyunhai Sugar Refinery to provide order-based agricultural services for local farmers. Ar Horqin Lingyunhai Sugar Refinery produces 62,000 tons of sugar annually, which requires 1 million tons of sugar beets as raw material. Meeting this demand requires planting more than 300,000 mu (20,000 hectares) of sugar beets. Through advanced technology, superior products, and end-to-end service, Sinochem MAP builds a bridge between the sugar factory and the farmers’ cooperatives, guaranteeing close cooperation between the sugar producer and sugar beet growers.

Diagram of Sinochem’s MAP industrial poverty alleviation model

This tripartite division of labor and cooperation has brought tangible benefits to the sugar factory:

1) increase in sugar beet’s sugar contents, stable quality and lower production costs

2) improved efficiency and quality

3) sufficient supply of raw materials

4) Additional market for all farmers and lower planting risks and culminates in a closed-loop, sustainable and virtuous industrial supply chain.

● Constructing and operating the MAP Technical Service Center

To comprehensively advance agricultural modernization in Ar Horqin, Sinochem Group invested about 25 million yuan (3.707 million U.S. dollars) to build a modern MAP technical service center in Ar Horqin Banner. Eleven professional and dedicated agronomists are stationed in the countryside, where they take root in the fields and provide year-round services to farmers, including planting-plan development, screening varieties, full nutrition and plant protection services, free agronomic training, and field guidance. With the support of the MAP Technical Service Centre and the agronomist team, the local government joined with MAP to support the agricultural cooperatives of six villages, including Bafang, Xinjian, Hongxing, Fangshen and Tianshan, in 2019.

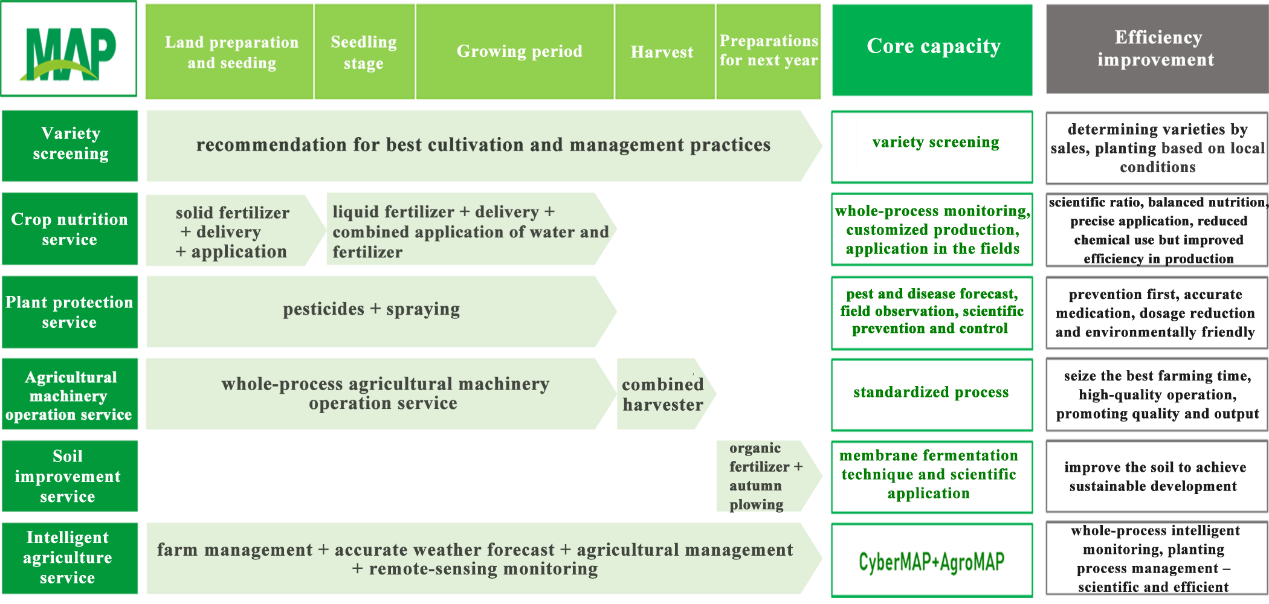

● Whole-process sugar beet planting solution

(1) Selecting the high-quality variety

After accounting for the ecological and climatic characteristics of Ar Horqin, MAP has selected the high-yield and high-sugar SD13829 sugar beet variety for farmers’ cooperatives.

(2) Developing customized, scientific crop nutrition program

MAP develops scientific whole-process beet-nutrition programs for farmers, and produces customized base fertilizer and topdressing products based on these programs. At the same time, special fertilizer-spreading machinery and equipment are used to distribute the base fertilizer to the field and provide accurate fertilization service.

Through these customized nutrition services, farmers’ cooperatives have noticeably reduced labor, time costs, staff labor intensity and effectively elevated the absorption rate of fertilizer nutrients .

(3) Developing customized, scientific plant protection package program

To adjust for diseases and insect pests that appear in different plots over the years, the MAP Ar Horqin center creates scientific plant protection package plans. These plans provide a set of clear and standardized operation procedures covering the usage, amount and application of pesticide products at different stages, ensuring the efficacy of weeding, disease prevention, and insect control.

(4) Providing digital agriculture solutions

MAP’s intelligent agriculture system, a digital agricultural platform independently developed by MAP, energizes the sugar beet production process.

With this intelligent agriculture App, farmers can stay on top of conditions in the field, more effectively managing labor, administration and operations, while a Map agronomist can inspect more than 300 hectares of land, which like “clairvoyance” to the farmers.

The digital tool optimizes the traditional production process, improves the efficiency of agricultural production and management, promotes agricultural modernization, improves the management efficiency of first-line agricultural services, and establishes a digital agricultural service platform.

III. Beneficiary description – outcomes and outputs

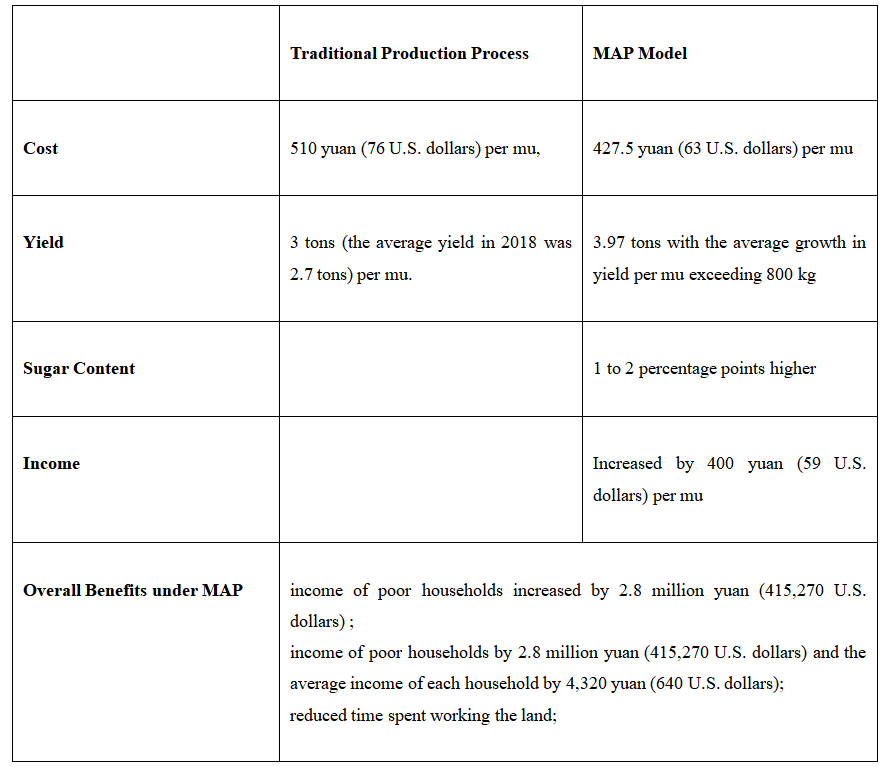

The project provided full service for six farmers’ cooperatives (involving 774 farmer households, including 135 poor households), covering 5,970 mu (398 hectares) of sugar beets, reduced average production costs by 82.5 yuan (12.23 U.S. dollars) per mu, increasing output by more than 800 kilograms, raising the sugar content in local sugar beets by around 1 to 2 percentage points, and increased average income per mu by 400 yuan (60 U.S. dollars) per year, average income per household by 4,320 yuan (640 U.S. dollars) per year, and overall income by 2.8 million yuan (415,270 U.S. dollars) per year.

The MAP Agricultural Technical Service Center constructed by Sinochem Agriculture

The service model for the MAP end-to-end solution

● Increased income for local farmers

● Local farmers inspired to start their own businesses

● Sustainable development of agriculture

● A replicable and propagable MAP model in China

The MAP poverty alleviation model created by Sinochem Agriculture has strong replicable and propagable elements, and has been well verified in China. By May 2020, Sinochem Agriculture had built and put into operation 246 MAP technical service centers and 275 MAP farms across the country, planting rice; wheat; corn; and other staple and cash crops such as fruits and vegetables, as well as distinct local crops including cotton, alfalfa and sugar beets. Planting and harvesting has been transformed from "living at the mercy of the weather" to "farming with agricultural aids ".

Source:

This article is excerpted from Global Solicitation on Best Poverty Reduction Practices.

Category

Improving Industrial Development Through the MAP Poverty Alleviation Model

Contributor

Improving Industrial Development Through the MAP Poverty Alleviation Model

Country

Case Study