I. Harvesting

Cassava tubers are bodies of nutrients and have no distinct physiological maturity. Cassava maturity refers to the stage at which the cassava produces maximum tuber yield and has maximum starch content throughout the year and can then be harvested.

Cassava harvesting tool

Cassava can be harvested by hand or machines. Generally cassava is harvested by hand when it is planted in a small scale. All the branches of the plants are cut off and the primary stems remain and then are pulled up by hand or by using cassava puller to harvest the cassava tuberous roots; cassava planted on ridges or on a large scale in flat or gently sloping land can be harvested mechanically: the plants are cut to leave primary stems 10cm above the ground, and ploughs without scrapers are mounted onto the tractor to loosen the soil and turn the cassava roots which are then collected by hand.

II. Stem Storage

• Stacking in the open field

A humid site under shade on the lee side is selected and the soil is loosened with hoes. Stems are stacked vertically on the soil with the distal end of the stem touching the soil, then covered on the top with grasses and watered to moisten the stems and soil. It is better to stack the stems in the areas where no frost occurs in winter.

• Furrow storage

Select a land sloping from the north to the south with well drained sandy soil. Furrows are dug 1.5-2.0m wide, 50-60cm deep without limited length. The stems are placed flat in the furrows, piled up1.0m high and covered 10cm deep with soil and then with straw, around which drainage ditches are made.

Furrow storage can be practiced in the area where frost occurs in winter.

III. Processing

Cassava roots are not tolerant to storage, and they deteriorate in quality and then rot 3-7 days after harvest. Processing is necessary. Cassava can be made into various types of food, can be sliced and dried as chips, pressed to extract starch and to produce alcohol.

Technical process for processing cassava starch: cassava➝clean and rinse➝grounded➝fine screen➝screen to remove sand➝refinery of starch➝dehydration➝drying➝packaging.

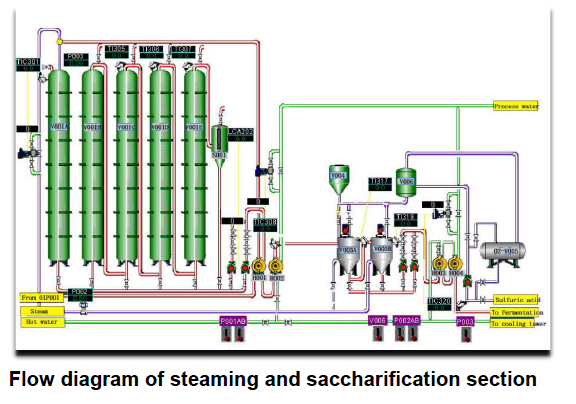

Technical process for cassava alcohol: cassava➝grounded➝mixed with additives➝steam➝saccharification➝fermentation➝distillation➝alcohol.

Starch can be used for deep processing in fermentation industry, sugar industry and chemical industry. It can be used to manufacture not less than100 types of fine chemicals such as citric acids, glutamic acids lysine, cassava protein, sucrose, fructose, sorbitol and mannitol, which have economic benefits tens and scores folds higher than the cassava itself. High value added products derived from cassava are of great significance in encouraging development of the cassava industry.

Excerpted from:

the Collection of Pamphlets for Practical Farming Techniques for Tropical Agriculture: Cassava Cultivation Compiled by Chinese Academy of Tropical Agricultural Sciences (CATAS)

Category

Harvesting, Storage and Processing of Cassava

Contributor

Harvesting, Storage and Processing of Cassava

Country

Technical Solution