The “Food-Gas Cycle” mode linked to biomethane has significant affection in boosting sustainable food production. The successful practice of “Food-Gas Cycle” mode including several key technologies and methodologies. We give the step-by-step guide for implementation details here, and point out the potential challenges may rise during the implementation process, also propose several highlight important factors precautions should be considered, and illustrate that villagers’ committee and agricultural machinery cooperative are the 2 key success factors. The effectiveness of "Food-Gas Cycle" from the perspective of smallholders, town government and biomethane project owners is analyzed, the “Food-Gas Cycle” mode is flexible, which can adapt to different scale, yet some potential challenges may rise when scale up. It has significant positive environmental impacts, and would be the optimal solution for securing food production and mitigating climate change. In addition, this mode can be extended to many forms, which can help to realize sustainable development in many fields of agricultural production area.

1. Problem Definition:

China faces the triple challenges in promoting the sustainable promotion of food production capacity. First, the return of large quantities straw to the fields over long period has exceeded the capacity of land to accommodate it. Secondly, due to the low benefits, farmers don’t have capacity to implement the fertilizer and pesticide reduction, and promote the ecological recycling. Thirdly, rural areas have been facing the shortage of clean energy supply, which not only affects farmers’ livelihoods, but also severely restricts the development of facility-based agriculture and agriculture-related industries. Yutian New Energy enterprise, with the production of biomethane as a link, through advanced stem-and-spike harvesting and anaerobic fermentation technologies, to construct the multiple subjects interest linkage mechanism, which can effectively solve the above issues, and construct a “Food-Gas Cycle” mode.

2. Technical Approach:

The successful practice of “Food-Gas Cycle” mode including 2 key technologies and 1 key methodologies.

(1) Key Technologies

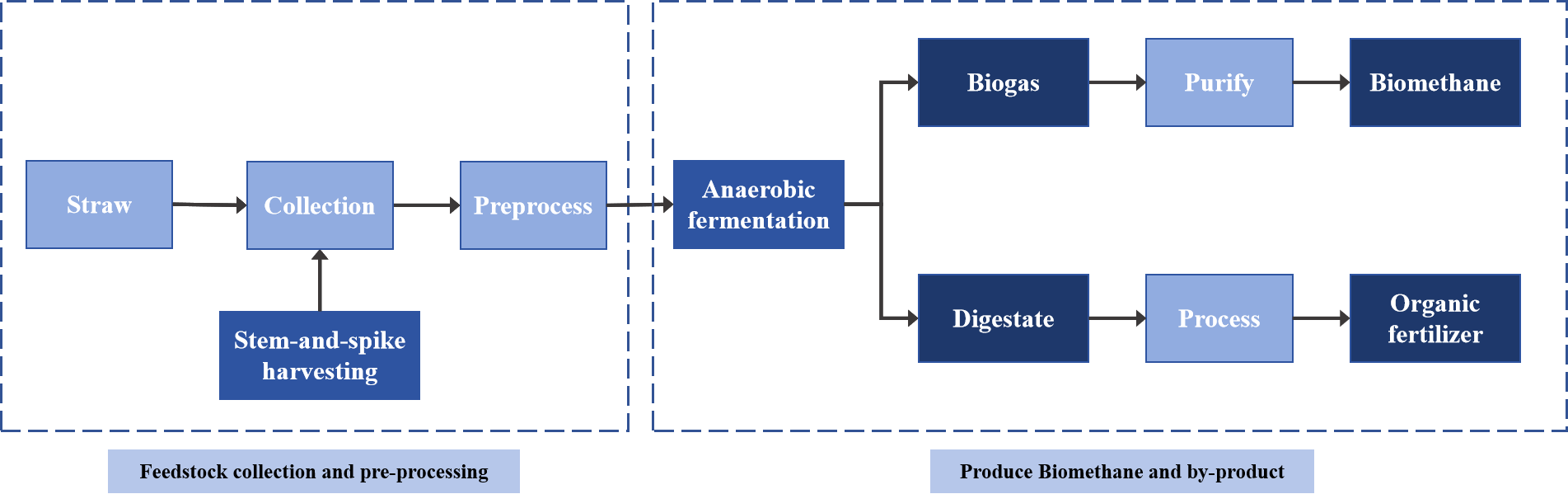

Key technologies include the advanced stem-and-spike harvesting technology and anaerobic fermentation technology.

Stem-and-spike harvesting technology refers to the modernized machine capable of harvesting corn and straw in one go, with high efficiency and utilization rate. Traditional corn harvester to harvest corns, in the process will be crushed straw scattered in field, causing the straw resources recycling difficulties especially for smallholders.

The anaerobic fermentation technology refers to the process in which organic materials (straw, manure from livestock and poultry, municipal waste, etc.) are decomposed and metabolized by various types of microorganisms under certain moisture, temperature and anaerobic conditions, ultimately resulting in the formation of a combustible mixture of gases like biomethane and carbon dioxide. It is a way to resourcefully utilize waste and produce renewable energy and relevant organic by-product.

Figure 1 Biomethane Production Flow Chart

(2) Methodology

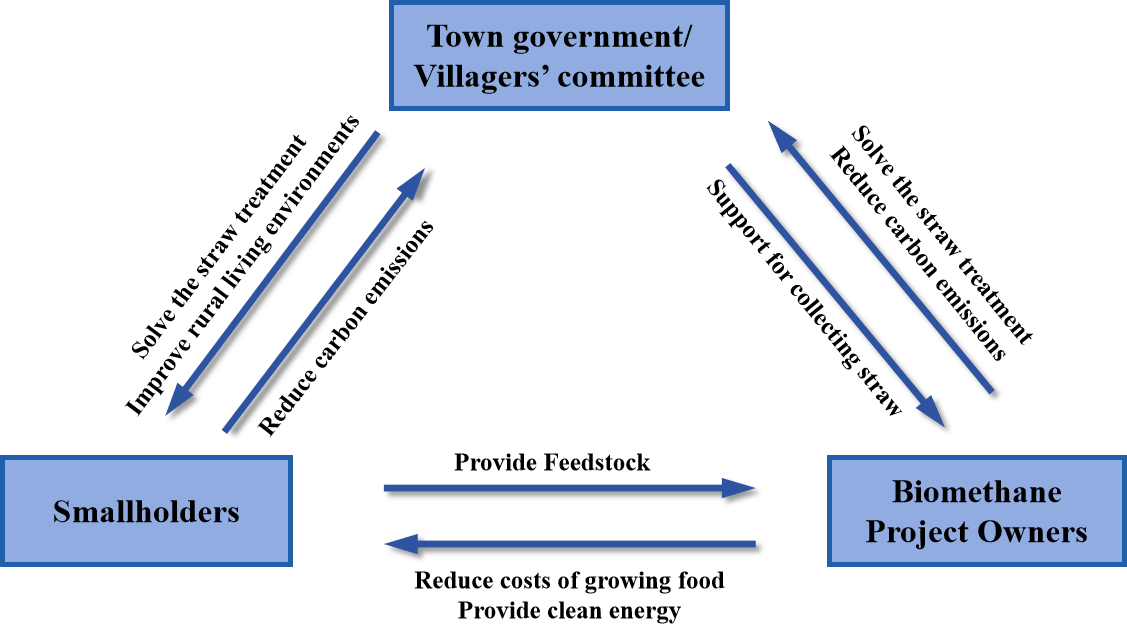

The key methodology is the construction of interest linkage mechanism, which refers to the synergistic and cooperative relationship established among multiple subjects through cooperation in order to realize the common goals of interests or to achieve the win-win situation.

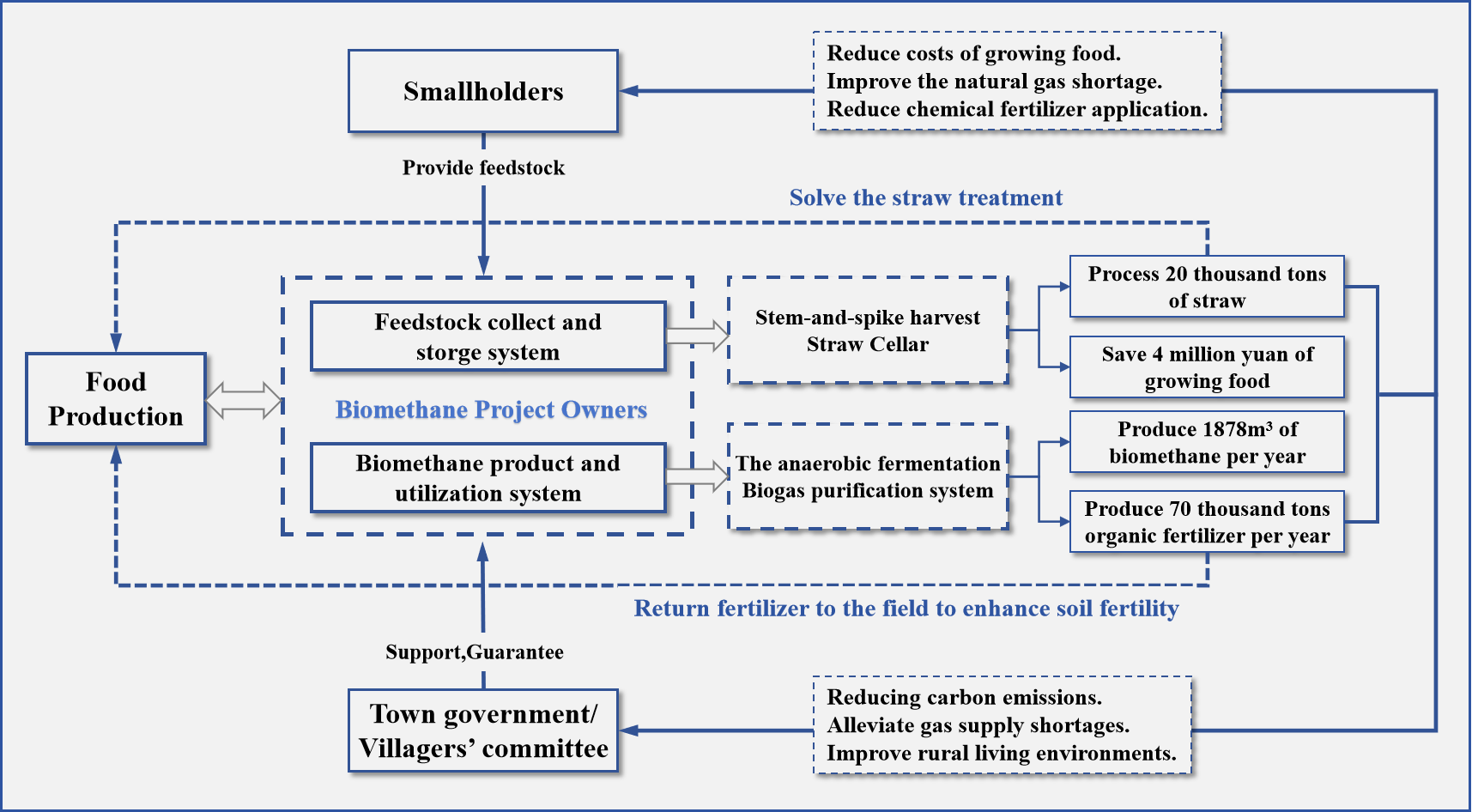

Figure 2 The Interest Linkage Mechanism

“Food-Gas Cycle” mode has the several applicable conditions:

i) Smallholders face agricultural waste disposal challenges, which imply there should be with sufficient production of feedstock, such as straw, livestock and poultry manure.

ii) There is a demand for the produced-biomethane, the biomethane project owners can be profitable.

3. Implementation Details

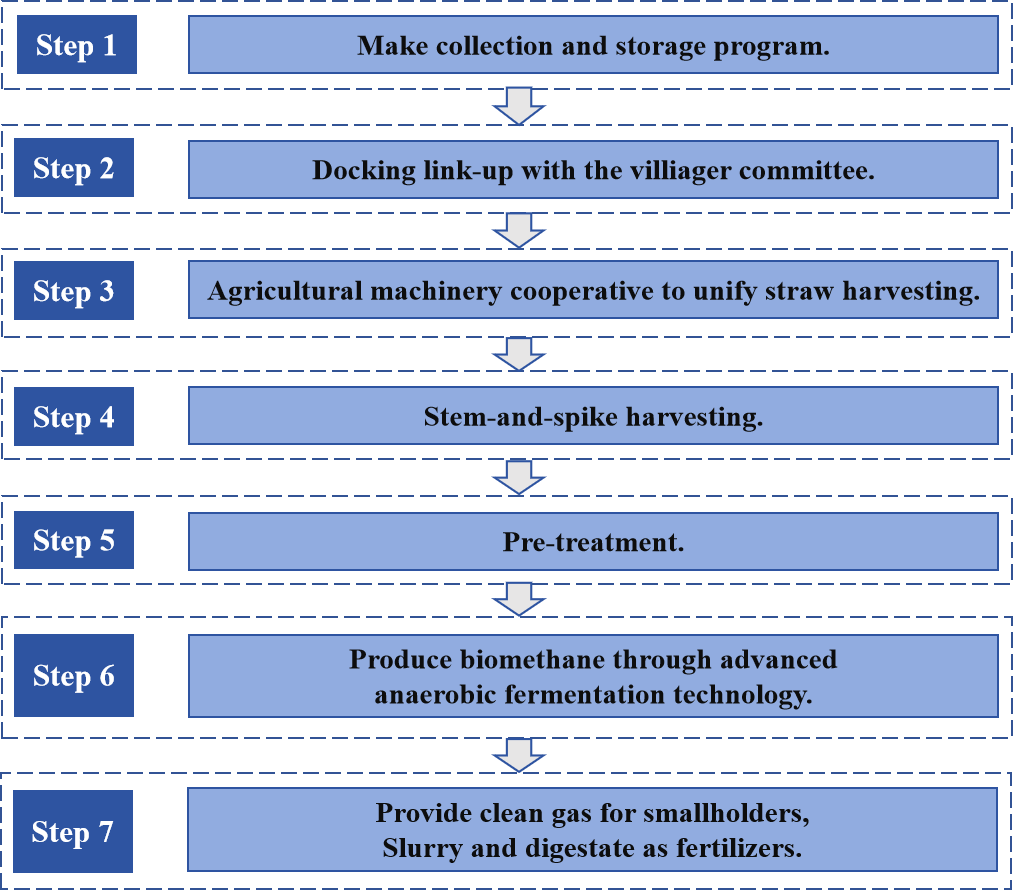

Here we give the step-by-step guide on how the solution is implemented here.

Step1: According to the scale of the biomethane project, making the feedstock collection and storage program.

Step2: Docking link-up with the town government and villagers’ committee to publicize straw collection activities, and to determine the collection plots, quantities and expenses.

Step3: Contact with agricultural machinery cooperative to determine the service price and unify straw collection.

Step4: Automated clean separation of corn and straw by stem-and-spike harvesting machine, simultaneous crushing straw, and uniform unloading the corn into farmers’ transporters.

Step5: Transportation of crushed straw to cellar site for pre-treatment (compacting to remove air and sealing), the purpose is anaerobic environment for acidification and fermentation to inhibit the propagation of harmful flora.

Step6: Biogas is produced through advanced anaerobic fermentation technology and purified to obtain biomethane, simultaneously get the by-products such as slurry and digestate.

Step7: Connect produced-biomethane to local gas pipelines to provide affordable clean gas for local households, applying the slurry and digestate as fertilizers through the provision of socialization services to smallholders, and realize the “Food-Gas Cycle”.

Figure 3 The Implementation Details for “Food-Gas Cycle”.

The potential challenges may rise during the implementation process.

Firstly, how to structure an effective organizational mode to collect straw from smallholders to ensure the stable and continuous supply of gas-producing feedstock, is the potential challenge may rise during the “Food-Gas Cycle” mode. In the process of collecting straw, smallholders may not cooperate and even raise the straw collection price, leading to high costs of feedstock and risk of interruption of feedstock supply.

Secondly, the potentially cost of providing produced-biomethane to stallholders or the demanding company and industry is another potential challenge. For areas with local gas pipeline, connecting produced-biomethane to pipeline network is the effective solution, otherwise, the transportation cost should be considered.

Several highlight important factors precautions should be considered.

i) The biomethane project owners should do adequate research beforehand, including feedstock resources, the demand market of biomethane and the local pipeline networks.

ii) The amount of straw collected should be determined according to the production situation, to avoid the situation of too much collection and storage cannot be eliminated.

iii) Cooperation with town governments and community organizations should be sought, collecting feedstock from smallholders without their help would be the challenging task.

4. Effectiveness:

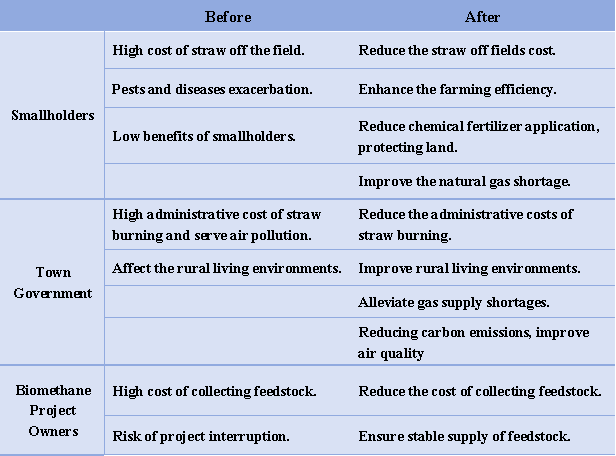

The effectiveness of “Food-Gas Cycle” mode can be illustrated from smallholders, town government/villagers’ committee, and biomethane project owners perspectives, the brief version is referred to Table 1.

(1) Smallholders

• Before

Local farmers are confronted with the high cost of straw off the field, 1200yuan/ha, which induce the high cost of growing food. Meanwhile, Pests and diseases exacerbation after straw is simply crushed and returned to the fields, leading to the land quality decline, food production reduction and low benefits of farmers.

• After

The direct benefit is reducing the straw off fields cost, it's gone from 1200yuan/ha to 900yuan/ha.

saving 4 million yuan per year for farmers in the neighboring 13333 hectares of cropland.

At the same time, straw after standardization off the fields to leave less stubble, enhancing the farming efficiency, and reducing the amount of fertilizer and pesticide application, protecting land. Return biogas and digestate to land, reducing chemical fertilizer application and enhancing land fertility.

In addition, biomethane as a supplementary source of natural gas, which can improve the natural gas shortage for farmers in winter.

(2) Town government

• Before

Town government face 2 main difficulties, one is that straw burning occurs from time to time, induce severe air pollution and high administrative cost of straw burning especially under the context of straw burning ban. The other is that straw piled indiscriminately, seriously affecting the rural living environments.

• After

The benefits of “Food-Gas Cycle” have several perspectives.

Firstly, it can reduce the administrative costs of straw burning and improve air quality. Secondly, it can significantly improve rural living environments.

Thirdly, it also alleviates gas supply shortages, and reduce the carbon emissions by replacing traditional fossil fuel.

(3) Biomethane Project Owners

• Before

Some biomethane projects owners have to undertake high cost of collecting feedstock, and with the risk of project interruption due to untimely supply of feedstock.

• After

The “Food-Gas Cycle” significantly reduce the cost of collecting produced-biomethane feedstock, ensuring the feedstock in stable supply.

Table 1 The effectiveness of “Food-Gas Cycle” mode

Villagers’ committee and agricultural machinery cooperative are the 2 key success factors.

Villagers committee has strong appeal and credibility among farmers in China. If biomethane project owners dock link-up with farmers for straw collection on their own, they face high communication and transaction costs, and even the risk of interrupting the operation of the project due to insufficient and untimely supply of feedstock.

Villagers committee coordinate the organization of farmers, building bridges between biomethane project owners and smallholders, which is the key reason for the successful practice of the “Food-Gas Cycle” mode.

Agricultural machinery cooperative is new and typical rural business organizations in China. The biomethane project owners dock link-up with it, significantly reducing the communication costs to directly dock link up with agricultural mechanics and smallholders, also ensuring the quality of feedstock and improving collection efficiency.

Figure 4 The “Food-Gas Cycle” Mode.

5. Scalability

The “Food-Gas Cycle” is flexible, which can adapt to different scale.

Scaling down indicates the “Food-Gas Cycle” implemented in small area, its easier to organize and coordinate small-scale smallholders, agricultural machinery cooperative, also medium-sized biogas projects are sufficient to process straw feedstock. Its easier at the implementation level, while scaling up is more challenging for implementation.

Actually, the potential challenges mainly reflect in several aspects:

(1) Straw feedstock collection is challenging.

Larger scale indicates more participating smallholders. How to mobilize smallholders’ participation, and construct the good organization and coordination mode is crucial. In addition, larger scale, straw feedstock transport distance is farther, induce higher transportation cost. At this point, it’s necessary to refine the collection and storage program for feedstock and plan well to reduce costs.

(2) How the produced-biomethane is consumed?

Given the rapid development of biomethane projects, processing large-scale agricultural waste is not a problem, however, how the produced-biomethane at back end would be consumed is the important problem. Firstly, in addition to the household’s demand, the gas demand of local industries needs to be considered. Secondly, access to local gas pipeline network is very important. High transport and storage costs would be generated if the produced-biomethane cannot be consumed locally.

6. Sustainability:

(1) Environmental impact

Obviously, “Food-Gas Cycle” has significant positive environmental impacts, as we analyzed in the effectiveness part. The above impacts mainly manifested in three aspects. Firstly, it can significantly reduce chemical fertilizer application, protecting land. Secondly, it has the effect of reducing carbon emissions and air pollution in rural areas by replace traditional fossil fuel. Thirdly, it helps to improve the rural living environments

(2) Ability to adapt to future changes

Securing food production and mitigating climate change are the important issues for the world today. “Food-Gas Cycle” play the crucial role in mitigating the two major problems mentioned above. Under the context of food security, upgrading the quality of arable land is the priority, the“Food-Gas Cycle”is highly effective in improving soil quality through promote straw off field and slurry and digestate return to field.

The key to address climate change is to reduce greenhouse gas into the atmosphere, as a zero-carbon product, produced-biomethane can significantly reduce carbon emissions as an alternative to traditional fossil fuel.

Apparently, the “Food-Gas Cycle” would be the optimal solution for securing food production and mitigating climate change.

7. Innovation

“Food-Gas Cycle” mode use biomethane as a link to solve the problem of waste treatment at the back end of food production, promoting the sustainable development of food production. In fact, the feedstock of biomethane project includes multiple wastes, in addition to straw, waste such as livestock manure, municipal organic waste and forestry waste resources. Thus “Food-Gas Cycle” can be extended to many forms, and realize sustainable development in many fields of agricultural production area. For example, to deal with the livestock waste from small-medium-size retail households, resulting in “Livestock-Gas Cycle”.

Source: Biogas Institute of Ministry of Agriculture and Rural Affairs(BIOMA)

Contact info: zhangmingming@caas.cn

Related links:

• China's No.1 Central Document for 2025

• Agrifood System Carbon Emissions and Reduction Policy: Insights from China and Africa

Category

“Food-Gas Cycle” Boosting the Sustainable Food Production

Contributor

“Food-Gas Cycle” Boosting the Sustainable Food Production

Country

Case Study