I. Background

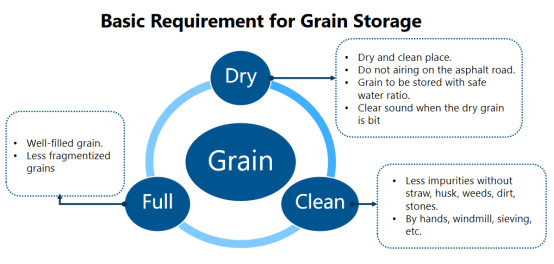

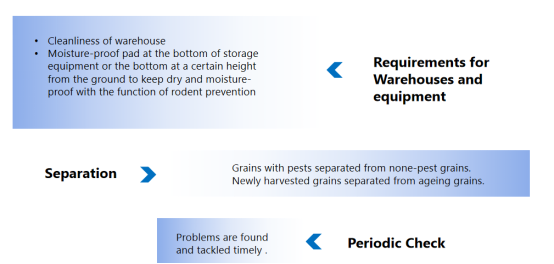

Farmer grain storage is an important component of overall grain storage and a crucial cornerstone for ensuring national food security. The characteristic of grain is that the higher the moisture and temperature, the stronger its respiration, which is conducive to the reproduction of harmful organisms. Therefore, the basic requirement for grain storage is that the grain itself and the storage site should be dry, clean, and at a low temperature.

This article will introduce the storage and pest control methods for three typical grain crops: rice, wheat, and corn.

II. Approaches

Basic Requirements of Safe Smallholder Grain Storage

● Methods of paddy storage

The husks of rice are relatively hard and can resist insect pests and the influence of external temperature and humidity to a certain extent. However, rice is not resistant to high temperatures and is prone to condensation, with almost no post-ripening period. In case of moisture regain or leakage, rice is prone to sprouting and yellowing, greatly reducing the stability of quality and storage. Additionally, rice which exposed to direct sunlight or subjected to sudden temperature drops after exposure may easily develop ‘burst waist’ (horizontal cracks on rice grains) , requiring special attention.

① The safe moisture standard for rice should be determined based on the variety, season, region, and climatic conditions. Generally, indica rice is below 13%, while japonica rice is below 14%. The fewer impurities and imperfect particles, the better. If the stored rice contains a large amount of moisture and impurities, it should be stored in a graded manner, dried in a timely manner, and screened or air selected to remove impurities.

② Due to its vigorous respiration, high grain temperature, and high moisture content, new rice should be ventilated promptly to reduce temperature and minimize moisture. Particularly during the cool autumn, when there is a significant temperature difference between the inside and outside of the grain pile, ventilation should be strengthened. Combining this with thorough flipping of the grain surface helps dissipate moisture and heat, preventing condensation. Mechanical ventilation can be employed if conditions permit. In winter, leverage the cold and dry weather for ventilation, reducing the grain temperature to below 10 ℃ and lowering the moisture content to safety standards. Before the spring temperature rises, cover and seal for secure summer storage.

● Method of wheat storage

Wheat has a thin seed coat, loose tissue structure, and strong moisture absorption ability; the post ripening period is long (most varieties have a post-ripening period ranging from two weeks to two months), and they have a certain degree of storage and heat resistance, but are susceptible to insect damage. During storage, attention should be paid to moisture and insect prevention.

There are three storage methods for wheat: conventional storage, heat tightness storage, and natural hypoxic storage.

① Conventional storage

After the harvest, Wheat should be thoroughly exposed to sunlight to reduce the grain moisture to below 12.5%, ensuring that the drying site is clean and not on the road, especially not on asphalt roads. Then, using methods like winnowing, remove impurities such as wheat straw, weeds, etc. Finally, store the wheat in the warehouse, taking measures to prevent moisture as well as rodent and insect infestations during storage.

② Heat tightness storage

The moisture content of stored wheat entering the warehouse should not exceed 12%, preferably below 11%. Before storing wheat, it is essential to conduct thorough warehouse cleaning and insect-killing procedures. When drying wheat, preheat the drying area, spread the wheat thinly on the drying field, allowing the wheat temperature to reach above 42 ℃, preferably 50 ℃ -52 ℃. In the afternoon, gather the grains , pile them up, keep them hot and stuffy for half an hour to one hour, then enter the warehouse while hot. It is advisable to fill the warehouse completely during the heat-tight storage to prevent the dissipation of wheat temperature, which could affect the effectiveness (if the wheat temperature upon entering the warehouse is about 46 ℃, it needs to be sealed for 2-3 weeks to achieve the insecticidal purpose).

③ Natural hypoxic storage

The natural hypoxic storage method is only applicable to the newly harvested wheat. After harvest, wheat should be dried and cleaned as soon as possible, and the warehousing and airtight work should be completed within a week. The primary condition for natural hypoxia storage is that the grain storage equipment must have sufficient airtightness. PVC soft airtight bin can be used for natural hypoxia storage; for other bin types, they need to be lined with plastic film. During the storage period, it is essential to frequently check the airtightness of the grain inlet and outlet, as well as the overall condition of the grain warehouse. If inadequate airtightness or damage to the warehouse body is discovered, the method of natural hypoxia cannot be continued. In addition, efforts should be made to prevent insects, moisture, rats, and conduct routine grain inspection.

● Method of corn storage

Corn germ is large, with strong hygroscopicity and vigorous respiration. Due to the high fat content and bacterial load in the germ, it is prone to mold and rancidity. Corn storage involves two stages: corn kernel storage and corn ear storage.

① Corn ear storage

During the storage of corn ear, the germ of the kernel is buried in the ear shaft, providing a certain level of protection effect against the insects and mold infection. In addition, the nutrients in the ear shaft can continue to be transported to the grain during the initial stage, enchancing nutrient content of the grain. Under long-term ventilation conditions in winter and spring, utilizing low temperatures helps gradually dry the corn. When the moisture content drops to 14.5% -15%, threshing can be initiated, and the corn can be transferred to kernel storage.

② Corn kernel storage

The key to safe corn storage is to improve the quality of storage and reduce the moisture content of grain. After harvest, corn should undergo thorough drying before entering the warehouse. After reaching a safe moisture level, it should be screened and cleaned, then stored in a closed and sealed manner during low-temperature and sunny days.

Ⅲ. Pest control

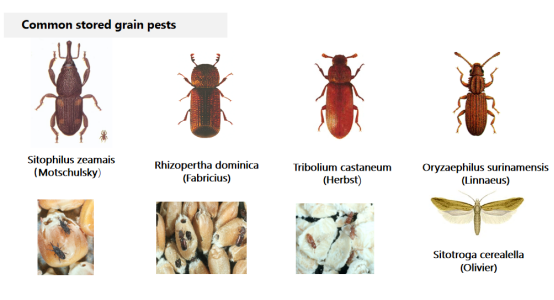

In general, the term “stored grain pests” in the grain system should encompass harmful insects, mites, birds, rodents and other arthropods that pose a threat to stored grain.

① Control of harmful insects

Currently, there are 226 species of stored grain pests, classified into beetles, moths and mites, with larvae being the most harmful stage. The optimum temperature for pest reproduction is 25 ℃ -35 ℃.

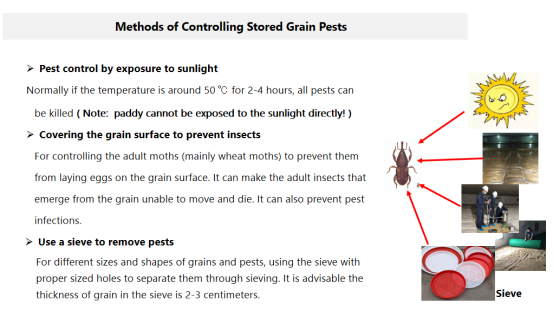

Priority should be given to the use of physical prevention methods such as airtight, sun turning and cooling. Sunlight exposure, covering the grain surface, screening, windmill and chemical control (mixing phosphorus insecticides into the stored grain) are commonly employed for pest control.

Common stored grain pests

Methods of Controlling Stored Grain Pests

② Prevention and control of rodents

Methods of preventing rodent infestation primarily include environmental prevention (clearing debris, blocking rat holes), using devices (rat traps, cages, sticky rat plates, etc.), biological rodent prevention (raising cats), and chemical prevention (using rodenticides). Among these, raising cats stands out as the simplest and most effective method for farmers to prevent rats.

Methods of Preventing Rodent Infestation

Ⅳ. Effect of the Solution

In the large-scale grain reserves of China, due to the favorable storage conditions, including warehouse facilities, equipment, and the use of advanced grain storage technology, rice can generally be safely stored for 2-3 years, wheat for 3-5 years, corn for 2-3 years, and beans for 1-2 years.

Source:

This article is excerpted from the [Quality Management and Pest Control for Smallholder Grain Storage] by Shengwei Xu, Senior engineer from Sinograin Chengdu Storage Research Institute.

Category

Quality Management and Pest Control for Smallholder Grain Storage

Contributor

Quality Management and Pest Control for Smallholder Grain Storage

Country

Technical Solution