I. Background

Located in the center of China's Yangtze River Delta, Zhangjiagang City is part of the "Fifth Grain Storage Ecological Zone" (subtropical monsoon climate moderate temperature high humidity grain storage area). The climate is mild and humid, and the pests pose a significant threat to grain storage. Additionally, during the drying and storage period of grain procurement, there is a phase where the grain condition is unstable, making the grain pile prone to heating and moulding. It is necessary to monitor and handle these issues promptly.

To achieve scientific prevention and control of insects and mould, and to reduce grain storage losses, Zhangjiagang City Grain Industry Development Co., Ltd. has established a pilot application standard system for "Fifth Grain Storage Ecological Zone" green grain storage technologies suitable for Zhangjiagang, using appropriate biological pest control methods combined with sub-low temperature grain storage technology.

II. Approaches

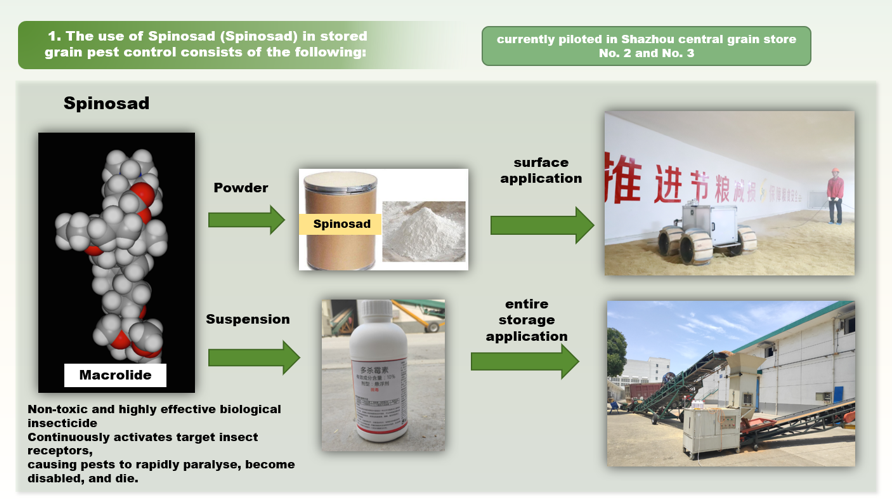

1)Application of Spinosad in Pest Control

Caption: 1. Methods of Applying Spinosad

Spinosad is a highly effective biological insecticide from the fermentation broth of Saccharopolyspora spinosa, a nicotinic acetylcholine receptor agonist. It can continuously activate the target insect's nicotinic acetylcholine receptors, causing rapid paralysis, disability, and ultimately death. Available as a white powder and a white suspension, the powder, composed of Spinosad and diatomaceous earth, can be mixed directly with grain for surface application. The suspension, composed of Spinosad and a volatile non-toxic organic solvent, requires dilution with water and is applied via nebulisers during the grain storage process. It degrades in the environment through a combination of photolysis and microbial degradation, used for entire storage application. Tests have shown that surface application in a quasi-low temperature environment can achieve 16 months of fumigation-free storage, while whole storage application in wheat stores can achieve 11 months of fumigation-free storage.

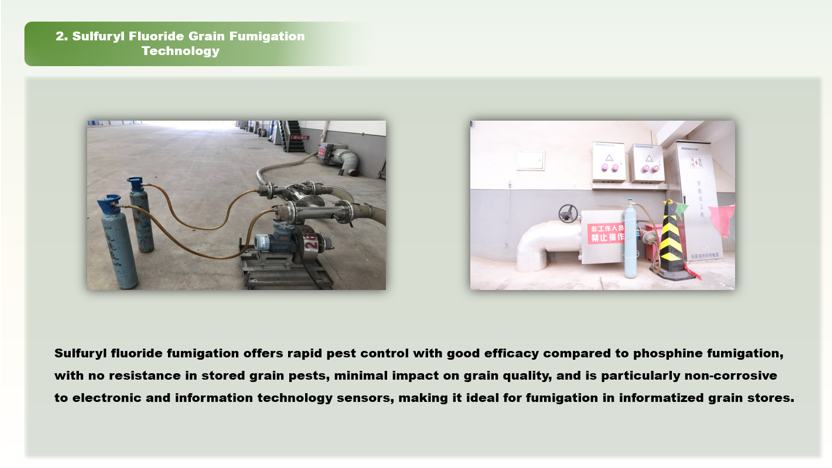

2)Sulfuryl Fluoride Fumigation Technology for Grain

Caption: 2. Sulfuryl Fluoride Grain Fumigation Technology

Sulfuryl fluoride is a gas fumigant that can be used for pest control in grain and food processing. The principle of pest control involves the fluoride ions formed by the decomposition absorbed by insects binding with calcium, potassium, and magnesium ions in the insect body, blocking enzyme activity within the insect, causing insufficient metabolism of sugars and fatty acids, leading to energy deficiency and death. Compared to traditional aluminium phosphide fumigation, sulfuryl fluoride has strong penetration, low residue, fast action, short dispersion time, convenient use at room temperature, no impact on grain germination rates, low toxicity to humans, and non-corrosive properties to metals, suitable for fumigation in informatised grain stores.

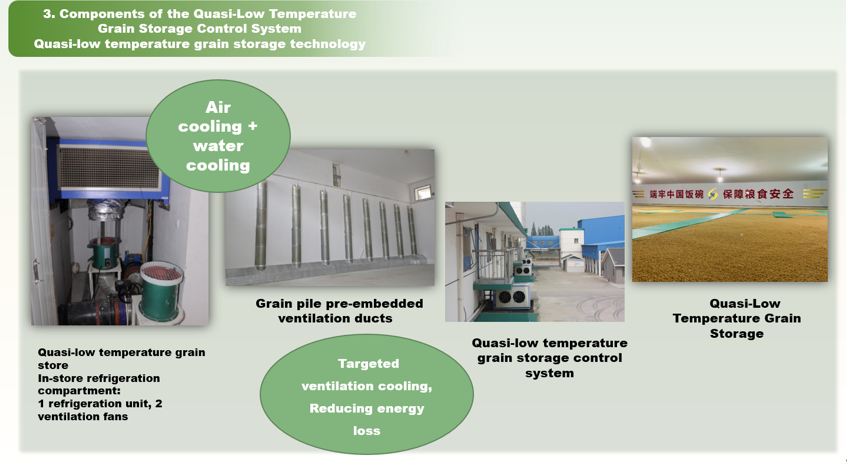

3)Quasi-low Temperature Grain Storage Technology

Caption: 3. Components of the Quasi-Low Temperature Grain Storage Control System

The specific approach of the quasi-low temperature grain storage control system involves setting up an in-store refrigeration compartment, equipped with one 5.5 kW refrigeration unit and two 1.1 kW ventilation fans, and pre-embedded ventilation ducts within the grain pile. On top of regular "air cooling" refrigeration within the grain store space, "river bottom water" is introduced as a cooling source for secondary "water cooling" of the refrigeration unit's heat exchanger, combining air and water cooling to address the challenge of high temperature protection for external refrigeration units during summer. Additionally, by improving the valve system of the pre-embedded ventilation ducts within the grain pile, targeted ventilation cooling is achieved, reducing energy loss during ventilation. This technology also enables even temperature cooling across the entire store, preventing heating, condensation, moulding, and suppressing pest and microbial activity, ensuring the safe storage of rice at relatively high moisture levels, reducing post-harvest drying losses by about 0.5%.

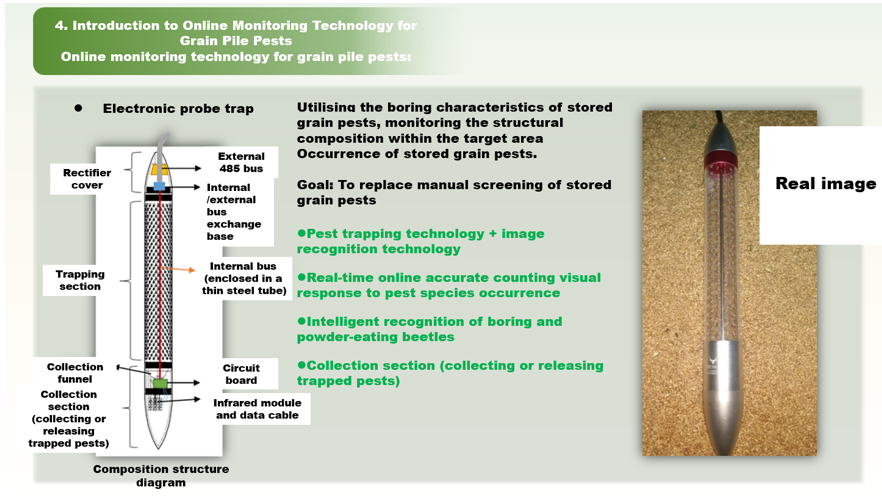

4)Online Monitoring Technology for Grain Pile Pests

Caption: 4. Introduction to Online Monitoring Technology for Grain Pile Pests

The online monitoring technology for grain pile pests aims to replace manual pest screening, accurately detecting the occurrence of pests within the grain pile and identifying pest species, providing crucial technical support for monitoring, early warning, and prevention of pests in grain stores. Currently, this technology has partially achieved the replacement of manual pest screening, enabling remote trap pest capture and pest identification among other functions.

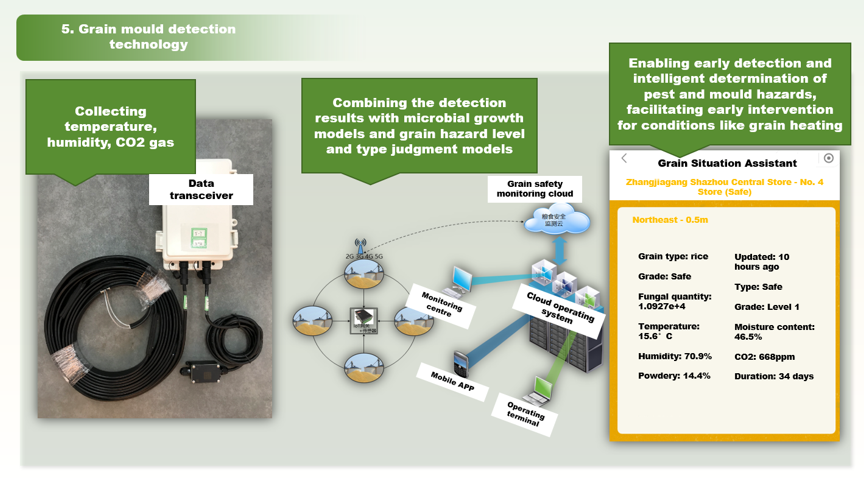

5) Grain Mould Detection Technology

Caption: 5. Application of Grain Mould Detection Technology

Grain mould detection technology involves collecting data on grain pile temperature, humidity, and carbon dioxide levels, combining the results with microbial growth models and grain hazard level and type judgment models. This enables early detection and intelligent determination of pest and mould hazards, facilitating guidance for grain stores to preemptively handle conditions like grain heating.

Ⅲ. Effect of the Solution

Quasi-low temperature stored rice has been well-received in the market, with auction sales prices online often exceeding similar grains by 0.5-2.5 cents per kg, generating revenue of approximately 3.5 million yuan. From 2021 to 2023, Zhangjiagang City Grain Industry Development Co., Ltd. consistently achieved the highest auction prices for rice in Jiangsu Province during the same period, with technological advancements in grain storage increasing annual benefits by more than 4 million yuan.

Source: Zhangjiagang City Grain Industry Development Co., Ltd.

Category

Subtropical Humid Zone Sub-low Temperature Grain Storage and Pest Control Technology System

Contributor

Subtropical Humid Zone Sub-low Temperature Grain Storage

Country

Technical Solution