Key Grain Storage Challenges Faced by Smallholder Farmers in China

Across China's vast rural areas, traditional small -scale farming often results in farmers having rather basic storage facilities and limited knowledge of proper grain storage practices. This frequently leads to considerable grain losses among farmers. A study conducted by the Sinograin Chengdu Storage Research Institute Co. Ltd in 2005 showed that, on average, farmers experienced about 8%~10% grain losses. Of these losses, approximately 49% were caused by rodents, 30% by mold, and 21% by insects.

The Three Major Causes of Grain Loss

With support from the National Food and Strategic Reserves Administration of China, the Sinograin Chengdu Storage Research Institute Co. Ltd has developed an innovative grain storage facility that transforms traditional storage practices. Taking into account the specific characteristics of grain storage among smallholder farmers in China-- who primarily store staple foods for approximately one year-- the institute has designed the steel mini silo for grain storage, a new storage solution tailored to the needs of smallholder farmers. This mini silo is specifically designed to store staple grains such as rice, which maintain a safe moisture content. It effectively reduces post-harvest losses, providing farmers with a practical means to minimize losses and increase their income. Moreover, the new storage facility helps prevent the formation of carcinogenic toxins like aflatoxin, which are produced by mold growth on grains. This ensures a higher quality grain supply to the public, laying a solid foundation for food safety right from the source.

Introduction of the grain storage steel mini silo

Steel mini silos can meet the grain storage needs of small-scale production.

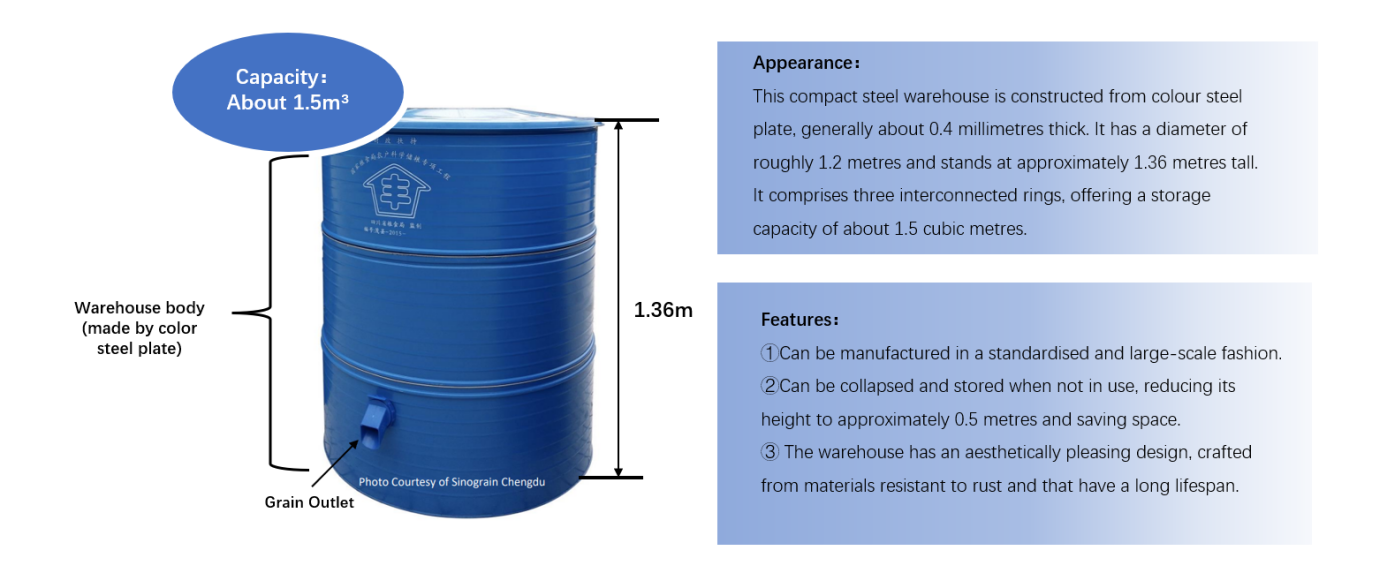

1. Appearance

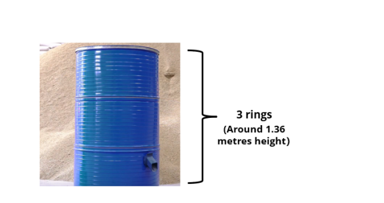

This steel mini silo is made of color-coated steel plate, generally about 0.4 millimeters thick. It has a diameter of approximately 1.2 meters and stands at approximately 1.36 meters tall. It comprises three interconnected rings, offering a storage capacity of around 1.5 cubic meters.

2. Features

The steel mini silo also has three distinctive features. Firstly, it can be produced in a standardized and large-scale manufacturing processes. This enables efficient mass production while maintaining consistent quality standards. Secondly, it offers remarkable portability and space-saving benefits. When not in use, the silo can be collapsed and stored, reducing its height to approximately 0.5 meters. This collapsible design allows for easy storage in limited spaces, making it highly convenient for farmers with varying storage needs. Lastly, the mini silo is designed with aesthetically pleasing design. It is crafted from rust-resistant materials that ensure a long service life.

After adopting the steel mini silo, pilot households have reported a significant decrease in grain storage losses. The average annual loss rate, previously at 8%, has been reduced to below 2%, proving its extraordinary efficacy in minimizing grain loss.

Manufacturing Process

The manufacturing process of the steel mini silo for grain storage mainly includes three main steps: cutting, creating upper, middle, and lower silo rings, and making silo cover and grain outlets.

Given its specific dimensions of around 1-1.5 cubic meters and weight of approximately 28 kilograms, the steel mini silo is not suitable for long-distance transport. It's advised to produce and process it locally in the grain-producing area. If long-distance transportation is required, different diameters of steel mini silo can be manufactured and stacked for transportation.

1. Cutting

In accordance with the diameter of the steel mini silo, the industrial material color steel coil, measuring 1 meter width, can be trimmed to the desired length dimensions. After cutting, the width of the color steel plate is typically 0.5 meters. For the silo lid and base material, industrial color steel plates of 1.2 meters wide are generally employed and need to be cut into a circular form using specialized equipment.

2. Creating Upper, Middle, and Lower Silo Rings

After trimming the color steel plate to a width of 0.5 meters, it can be linked together to form a cylindrical shape. Subsequently, the edges are rolled, and the interior is wrapped with iron wire. Specialized machinery is used to press raised and recessed major ribs on the upper, middle, and lower layers of the silo rings to aid accurate positioning during installation. In addition, smaller reinforcing ribs are pressed onto the silo rings to enhance stiffness. For the bottom layer of the silo rings, the silo base needs to be joined to the side walls of the bottom layer of the silo rings.

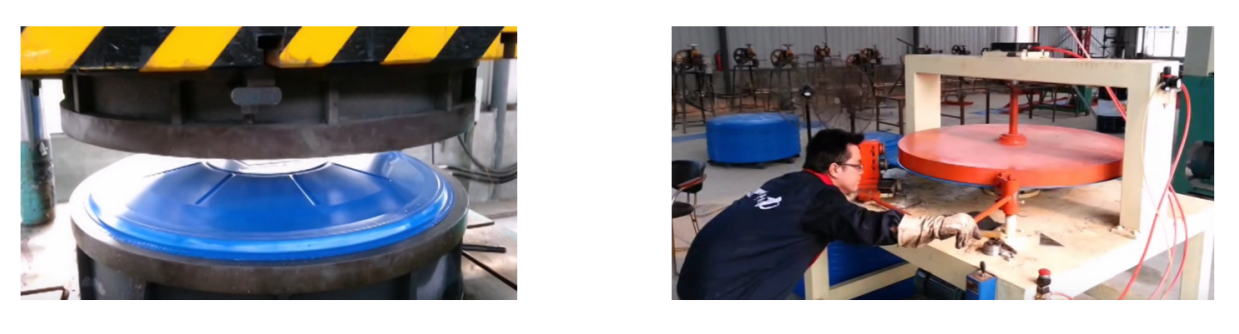

3. Silo Cover Creation and Grain Outlet Manufacturing

For the silo cover, it is typically molded and pressed in one go using a mold. After pressing, additional processes such as edge trimming, edge rolling, or wrapping with iron wire may be carried out. The benefits of this approach include its aesthetic appeal and robust strength.

Silo Cover Creation

For the grain outlet, it is usually created using injection molding with molds, utilizing plastic as the raw material. The benefits of this method include its aesthetic appeal and user-friendly nature.

Grain Outlet Manufacturing

Installation Process

(1) The color steel silo should be situated indoors. During assembly, begin by removing the silo lid and the third ring of the color steel silo. When operating, it's crucial to evenly grip both sides of the silo and exert upward force. To remove the second ring of the silo, follow the same process as removing the third ring.

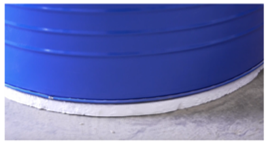

(2) After removing the necessary rings from the colored steel silo, position the first ring on a flat and level surface. It is recommended to use a high-strength foam damp-proof mat underneath for added protection.

(3) Install the grain outlet and begin loading the grain into the silo.

(4) To install the second ring, rotate it upside down by 180 degrees and fit it into the first ring. Ensure that it aligns properly and is secure. Once in place, you can continue loading grain into the silo.

(5) To install the third ring, replicate the method used for the second ring. Once installed, continue loading grain into the silo.

(5) Lastly, position the silo's top cover onto the third ring, and the assembly of the mini steel silo is completed. When we need to use grain, it can be discharged through the grain outlet.

Storage of the Silo

When the silo is not in use, it can be stored within the bottom ring to conserve space. Here's how: Firstly, rotate the second ring by 180 degrees and place it inside the bottom ring. Next, rotate the third ring by 180 degrees and position it inside the second ring. Finally, cover the silo with the top cover, placing it atop the third ring.

Usage Precautions

There are a few considerations when utilizing the mini steel silos:

(1) It is inadvisable to exceed three rings in height, with an optimal height of around 1.36 meters.

(2) The floor should be equipped with damp-proof mats. It's recommended to use rigid polystyrene foam boards as damp-proof mats. These mats not only guard against moisture but also prolong the silo's lifespan.

(3) When loading the grain, refrain from placing heavy objects filled with grain directly against the cylindrical walls of the silos from the top or side to avoid deformation of the walls.

Effect of the Solution

Efficient grain storage equipment is the most effective measure to reduce rodent damage and is crucial in minimizing post-harvest grain losses for farmers. Since 2004, the techniques in reducing grain losses for Chinese farmers' storage have been widely promoted and applied. Over 9.5 million sets of new grain storage equipment for smallholder farmers have been used in 26 provinces (autonomous regions, centrally administered municipalities) across the country. This initiative helps reduce annual grain losses by approximately 976,000 tons. The significant reduction in losses has had a positive impact on increasing income for farmers, as well as provided strong support in ensuring national food security.

Related links:

1. Study on Grain Storage and Loss Reduction Technology for Smallholder Farmers in China

2. Cloud School Courses on Grain Post-harvest Handling for Smallholders

3. Innovative Storage Solutions Enable Sichuan Farmers to Reduce Post-Harvest Losses

Category

Mini Steel Silos: An Innovative Grain Storage Solution for Smallholder Farmers in China

Contributor

Mini Steel Silos: An Innovative Grain Storage Solution for Smallholder Farmers in China

Country

Technical Solution