Background

Cassava is a critical staple food that feeds close to one billion people around the world, mostly in tropical areas. It can be made into many kinds of food across regions: in Africa, the roots are often soaked, sun-dried, and steamed to make a variety of traditional dishes; in Asia, cassava may be eaten directly, processed into flour or starch, or made into a wide range of snacks and desserts(see Figure 1). To keep up with growing and more diverse market needs, expanding cassava processing methods is becoming increasingly important for developing new products and improving food security.

Figure.1 Various products made from cassava as rawmaterial

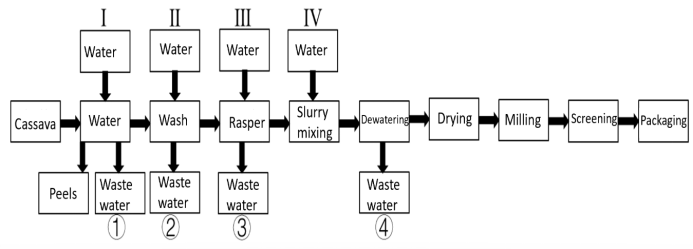

There are two common methods for producing cassava flour. One is the dry processing method, in which the cassava is cut into chips, dried, and then ground into powder. The other is the wet processing method, where the cassava is ground first,and the resulting cassava milk is dried afterward. This method uses water as a key part of the process. The water helps separate, clean, and dry the starch and fine fiber in the cassava, resulting in high-quality cassava flour. This document focuses on the wet processing method for making cassava flour.

Figure 2. Wet Processing Flow for Cassava Flour

Many small, traditional production setups do not have proper hygiene and safety controls. Without these safeguards, the flour is more likely to face issuessuch as microbial contamination, and the process cannot reliably remove the natural cyanogenic compounds in cassava, which can be harmful if not reduced to safe levels. For these reasons, establishing a controlled, machine-based wet processing line is essential. It provides a reliable way to mass-produce cassava flour that’s safe, consistent in quality, and high-grade for commercial use(see Figure 2).

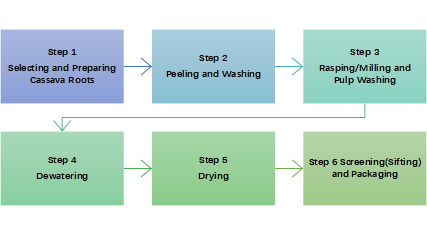

Six Key Steps in Wet Processing (see Figure 3)

Figure 3. Wet Processing Flow Chart

Step 1. Selecting and Preparing Cassava Roots

The process starts with picking out fresh, unbruised, and mold-free cassava roots. For safety, it is best to choose "sweet" cassava varieties instead of "bitter" ones. These sweet varieties naturally have low cyanide levels (no more than 50 mg of HCN equivalents per kilogram of fresh root). First, the roots go through aninitial cleaning step: vibrating screens or air classifiers are used to get rid of large, rough debris like stones, clumps of dirt, and leftover field waste.

Step2. Peeling and Washing

Roots are put into a Sand Removals and Peeling Machine (see Figure 4) where they roll around and rub against the inner surface or against each other-while being sprayed with clean water. This process effectively removes the outer skin, the inner cortex layer (which has more impurities and harmful cyanide compounds), and any stuck-on sand or dirt.

Power: 2200W

Processing Capacity: 5000 kg/hour

Figure 4. Sand Removal and Peeling Machine

In this step, a rotating drum is used to wash and peel the cassava roots. Theinside of the drum is lined with a rough, abrasive material. As the cassava roots roll inside the drum under the water spray, the friction helps remove the peel and any dirt stuck on the surface. Meanwhile, sand and other heavier particles sink to the bottom of the drum and are separated out.

After the initial peeling step, the cassava roots-- or the coarsely crushed pulp they have been turned into-- enter into this processing unit,the Slurry Washing Machine (see Figure 5). A large amount of water is used here for washing at this stage, making this stepcritical for the first round of purification. Thorough washing at this pointis key to ensure that the final product has a bright color and high purity.

Power: 1250W

Processing Capacity: 2000 kg/hour

Figure 5. Slurry Washing Machine

Step 3. Rasping/Milling and Pulp Washing

The cleaned cassava roots are fed into a high-powered rasp or mill. This machine (see Figure 6) smashes the roots into a fine pulp or slurry. During or immediately after rasping, a large amount of water is added to turn the pulp into a runny mixture that can be pumped easily through pipes. The added water serves a dual purpose: it facilitates the separation of starch granules and fine flour particles from the coarse fibrous pulp (bagasse), and it further washes away soluble impurities, including residual cyanide compounds, proteins, and sugars, thereby significantly improving the purity and whiteness of the final product.

Power: 37,500W

Processing Capacity: 2000 kg/hour

Figure 6. High-Capacity Rasping/Milling Machine

This is actually the core step of the entire wet processing method. The high-power machine is fitted with a rotating drum covered in tough, sharp studs, which completely breaks down the washed roots into a smooth, fine pulp. The slurry is then pushed through fine-mesh screens or filters to refine it further.

Step 4. Dewatering

The refined slurry, now separated from most fibers, contains a high percentage of water. The slurry is fed into a dewatering machine, such as a plate and frame filter press (see Figure 7). This is the key first step to remove excess water. Pressure is applied to the slurry, pushing water through special cloth filters and leaving behind a solid, moist "filter cake" (usually around 40% water content). This step is a big energy-saver: by getting rid of most water now, far less energy is needed for the final drying stage.

Specifications of Plate andFrame Filter Press:

Power: 1500W.

Filter Fineness: Retains particles, typically corresponding to 15-40 mesh screen size.

Figure 7. Plate and Frame Filter Press

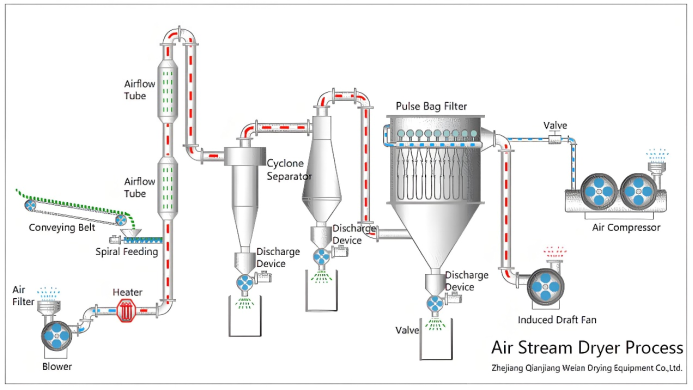

Step 5. Drying

A common piece of equipment for this step is an airflow drying system (see Figure 8). It has a tall vertical drying column: the broken-up wet filter cake is fed into the column, where it meets a high-speed stream of hot air. The intense heat dries the material almost instantly — water evaporates right away—and the dry cassava powder is then separated from the hot air using cyclone separators. This method works really well: it is efficient and keeps the starch in the flour from getting damaged.

Power: 300,500 W

Processing Capacity: 700-750 kg/hour

Figure 8. Schematic Diagram of an Air stream Drying System (Image source: Zhejiang Qianjiang Weian Drying Equipment Co., Ltd.)

Step 6. Screening (Sifting) and Packaging

The dried cassava powder might have a few small clumps that formed during the drying process. To fix this, the powder is passed through automated Packing Machine (see Figure 9)—this breaks up any lumps and ensures the final product has a uniform, consistent particle size. After screening, therefined cassava flour is immediately packed into moisture-proof bags. This stops it from clumping up or getting contaminated while in storage or being transported. The final packaging stage is fully automated: the dried, sifted flour is weighed and filled into bags without any manual handling.

Specifications of Automated Packaging Machine:

Processing Speed: 80-120 bags per minute.

Figure 9. Automated Packaging Machine

Scope of Application

Wet processing for cassava flour requires a significant investment in equipment and uses a lot of water. That is why it is most suitable for medium to large businesses—like dedicated processing factories or big agricultural cooperatives—operating in cassava-production regions. The advantages of this method are clear: it produces flour with higher purity, more consistent quality, and better color. These qualities make wet-processed cassava flour ideal for supplying large quantities to food manufacturers (for example, as an ingredient in baked goods, gluten-free products, or as a refined thickener) and for commercial retail packaging where high quality is essential.

Practical Application Cases

The viability and effectiveness of this technology are demonstrated by successful installations in different parts of the world (see Figure 10):

l Danzhou, Hainan Province, China: A modern processing plant utilizes this wet method to produce high-grade cassava flour for both domestic specialty markets and export. The controlled process ensures low cyanide levels and a bright white product, fetching a premium price.

l Republic of Congo: An industrial-scale wet processing line has been established to add value to local cassava production. This plant focuses on producing standardized flour for national and regional food security programs and commercial distribution, improving local income and reducing reliance on imported wheat flour.

Figure 10. Cassava Flour Wet Processing Production Lines (Left: Danzhou, China; Right: Republic of the Congo)

Conclusion

Cassava flour wet processing is a major step forward in turning one of the world’s most important staple foods into a safe, reliable, and high-quality ingredient. It follows a clear, step-by-step process with six key stages: picking and cleaning the roots, washing and peeling them, grinding into pulp (and washing the pulp), removing excess water and drying, then final sifting and packaging. This processing method removes cyanide compounds and impurities, ensuring the quality and safety of the final product.

Each stage uses specialized equipment, which ensures the process is efficient, clean, and scalable (meaning it can grow with demand). That is why it is a great fit for medium to large businesses and agricultural cooperatives. But the benefits go beyond just better processing: wet processing helps improve food safety, supports making gluten-free and specialty foods, reduces the need to import grains, and creates new ways for farmers in cassava-growing areas to earn money.

This technology is already working well in places like China and the Republic of Congo. It has huge potential to make food supplies more secure, open up new markets for cassava products, and promote sustainable farming. In short, cassava wet processing is not just a technical fix — it is a way to build healthier diets, stronger rural economies, and a more resilient global food system.

Supporting institutions:

· Tropical Crops Genetic Resources Institute, Chinese Academy of Tropical Agricultural Sciences

· Chinese Cassava Agro-technology Research System

Contact information: E-mail: liminglin@catas.cn

Category

Cassava Flour: Basics of Wet Processing Techniques and Required Equipment

Contributor

Cassava Flour: Basics of Wet Processing Techniques and Required Equipment

Country

Cassava Flour: Basics of Wet Processing Techniques and Required Equipment