Background

Cassava has become a critical staple food, supporting nearly one billion people in tropical and subtropical regions worldwide. What makes it so important? It is incredibly drought-tolerant, grows well in poor soil, and produces lots of carbohydrates. In Africa, cassava is a key crop for food security. Locals traditionally process the roots by soaking, fermenting, sun-drying, or steaming them to make foods like gari, fufu, and basic flours. In Asia, cassava is used in more varied ways—people eat the roots directly, or turn them into edible flour, starch, and all kinds of snacks, desserts, and baked goods. This global dependence on cassava means we need more diverse and scalable processing methods. These methods should meet different market needs while making sure the final products are safe and high-quality.

Cassava flour is made by grinding the whole cassava root, while cassava starch is extracted by isolating only the starch from the root. This difference gives cassava flour its own unique uses in various foods.

Usually, cassava flour is typically processed in two ways: the dry method and the wet method. This article focuses on the dry processing method, walking through the steps and equipment needed. We are focusing on this approach because it can help bridge traditional practices with modern food safety needs.

Why does that matter? Because cassava roots naturally contain toxins—specifically compounds called cyanogenic glycosides (like linamarin). If not removed properly during processing, these can release harmful hydrogen cyanide (HCN). Traditional small-scale or home processing methods are part of many cultures, but they often cannot reliably remove enough of these toxins or ensure the flour is microbiologically safe. That is where modern, hygienic dry processing comes in—it is a reliable way to produce safe, high-quality cassava flour suitable for both home cooking and commercial use.

Figure 1: Dry Processing Flow for Cassava Flour

Key Steps in Dry Processing

Step 1. Raw material selection

Good-quality cassava flour starts with picking the right roots. For making edible flour, it is best to choose "sweet" cassava varieties instead of "bitter" ones. These sweet varieties naturally have low cyanide levels (no more than 50 mg of HCN equivalents per kilogram of fresh root). The roots should be freshly dug up, firm to the touch, and free from rot, mold, or major bruises/damage.

Step 2. Peeling and Cleaning

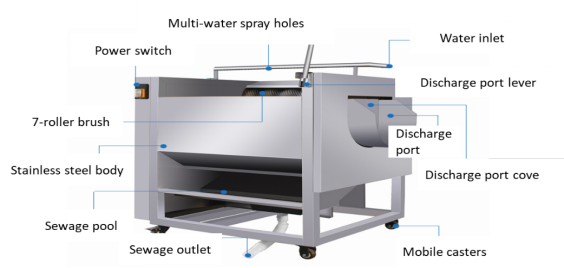

This step is crucial for removing cyanide. The cassava peel and the thin layer just beneath it have high levels of cyanide compounds. Mechanical peelers use rough rollers or blades to scrub off both the outer brown skin and that inner layer. After peeling, the roots are washed thoroughly with clean water to remove any leftover peel bits, sticky latex, and dirt on the surface. Doing a good job of peeling can get rid of 50-70% of the cyanide in the cassava, making it much safer to use.

See the machine used for Step 2 in Figure 2.

Power: 750W

Processing Capacity: 300 kg/hour

Figure 2: Peeling and Washing Machine

Step 3. Slicing

Next, the peeled cassava roots are cut into thin chips (about 2-3 mm thick) or shredded into fine strands using a machine. Making the roots this small drastically increases their surface area. This helps them dry quickly and evenly in the next step. Drying efficiently at this stage is important: it stops bacteria from growing and prevents enzymes in the cassava from causing spoilage or turning the chips brown. (See the machine used for this step in Figure 3)

Power: 1500W

Processing Capacity: 450 kg/hour

Figure 3: Slicing Machine

Step 4. Drying

Drying is the most energy intensive and quality defining step. The objective is to reduce the moisture content from about 60-65% (wet basis) in fresh roots to a safe storage level of 13% or lower. The recommended drying temperature is around 60°C. Going any higher than this can compromise the quality and functional properties of the final product. Lower temperatures prolong the drying time, increasing energy costs and the risk of microbial proliferation or non-enzymatic browning reactions, which darken the product and affect flavor. Cabinet dryers, tunnel dryers, or solar-assisted dryers can be employed, with controlled air circulation to ensure even drying. (See the machine used for this step in Figure 4)

Power: 2150W

Processing capacity: 600 kg/hour

Figure 4: Drying Machine

Step 5. Grinding

The dried cassava chips are now brittle and easy to break. They are fed into a hammer mill or grinder to first turn them into a coarse powder (called "meal"). This step makes the material easier to work with and gets it ready for the final fine grinding. (See the machine used for this step in Figure 5)

Power: 2200W

Processing Capacity: 100 kg/hour

Figure 5: Grinding Machine

Step 6. Sieving

The coarse cassava meal is then put through a fine mill—such as a plate mill, pin mill, or cyclone mill—to grind it down to the desired fineness for the final flour. After grinding, the powder is sifted using a vibrating screen or plansifter.

For general-purpose cassava flour, a standard 80–100 mesh screen (about 180–150 microns) is commonly used. This ensures the floor has a smooth texture that works well in most recipes. Any particles that are too large to pass through the screen are sent back to the mill for regrinding, which helps maximize the amount of usable flour produced. This entire step is key to making sure the flour is uniform in texture, which is essential for consistent results when cooking or baking with it. (See the machine used for this step in Figure 6)

Power: 550W

Particle Size: 100 mesh

Figure 6: Sieving Machine

Step 7. Package

Immediately after sieving, the flour must be packaged to prevent moisture reabsorption from the humid tropical atmosphere, which can lead to caking and mold growth. Packaging in moisture-proof, food-grade polypropylene bags or laminated sacks is standard. Proper labeling with production date, expiry date, and nutritional information is essential for market readiness. Storage should be in a cool, dry, and well-ventilated warehouse to extend shelf-life, which can be 6-12 months under optimal conditions. (See the machine used for this step in Figure 7)

Power: 550W

Processing capacity: 150 kg/hour

Figure 7: Packaging Machine

Scope of Application

Dry processing is mainly used for small-scale or household production, and it is especially suitable for individual farmers and small workshops in tropical and subtropical regions. It works well in areas with limited money, scarce water resources, and no professional technicians, with the final products mostly used for local daily cooking and small-scale sales nearby. Compared with wet processing, dry processing has clear advantages: it needs much less initial investment, as it only requires simple equipment and no large amounts of water or supporting water treatment facilities, making it affordable for smallholders; its production process is simple and easy to master, so farmers can complete the whole process by themselves without professional help. In addition, its industrial chain is shorter, with a faster cycle from harvesting cassava roots to producing finished flour, allowing farmers to increase their income quickly on their own.

Case Studies

Cassava flour dry processing production line have been successfully established in Danzhou City, Hainan Province, China, and Abuja, Nigeria, achieving positive results.

Figure 8: Cassava Flour Dry Processing Production Line

Conclusion

Dry processing of cassava flour is a practical primary processing method that turns cassava into storable, edible powdered products with relatively low investment. As a traditional approach with low capital expenditure, it adopts core procedures including peeling, washing, slicing, drying and grinding. Its simple operation makes it ideal for small-scale or household production. Under specific regional and economic conditions, this method plays a vital role in extending the cassava industrial chain and boosting farmers’ income.

This technology is already working well in places like China and Nigeria. It has huge potential to make food supplies more secure, open up new markets for cassava products, and promote sustainable farming.

Supporting institutions:

· Tropical Crops Genetic Resources Institute, Chinese Academy of Tropical Agricultural Sciences

· Chinese Cassava Agro-technology Research System

Contact information: E-mail: liminglin@catas.cn

Category

Cassava Flour: Basics of Dry Processing Techniques and Required Equipment

Contributor

Cassava Flour: Basics of Dry Processing Techniques and Required Equipment

Country

Cassava Flour: Basics of Dry Processing Techniques and Required Equipment