Technical Background

For a long time, apart from being used for asexual reproduction, most cassava stems have either been burned or discarded at will. This not only causes serious environmental pollution butalso leads to the reckless waste of resources. (see Figure 1).

Figure 1. Cassava stem

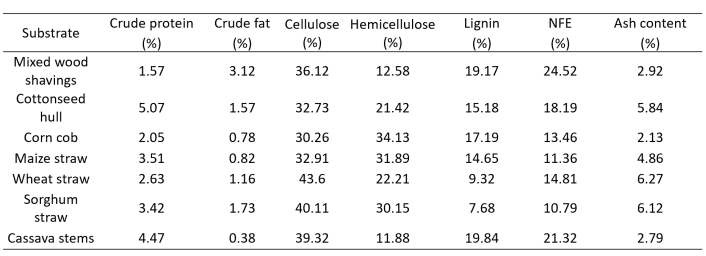

Cassava stems have distinctive traits: their protein content is a decent 4.47%, and cellulose content is as high as 39.32%. The levels of crude protein and cellulose in cassava stems are significantly higher than those in mixed wood chips andare on par with those in cottonseed hulls. The content of other components is not much different from that of common nutrient materials. Especially after being crushed, cassava stems are better than mixed wood chips in water retention and air permeability.

Therefore, cassava stems are excellent substrate materials for growing edible fungi. Using cassava stems to cultivate edible fungi can not only solve the problem of insufficient raw materials for culture media in the edible fungus industry, but also reduce environmental pollution caused by the massive disposal or incineration of cassava stems. (see Figure 2).

Figure 2. Black fungus cultivated on cassava stem as substrate

What is more, compared with wood, cassava stems are available in large quantities at a much lower price. Applying them to edible fungus cultivation can thus greatly cut down production costs. At present, this technology has been promoted and put into application to a certain extent in China (Table 1).

Table 1. Component Analysis of Cassava Stems

Implementation Measures/Steps

Most edible fungi can be cultivated using cassava stems. In this paper, the black fungus is selected as a typical example for detailed illustration.

Two main cultivation methods are used for growing black fungus: open-field cultivation and hanging bag cultivation. The appropriate method should be selected based on the specific growing conditions. (see Figure 3).

1. Preparation Stage

1.1 Open-field Cultivation Mode: Select a leeward, sunny, flat area with small day-night temperature differences and high humidity, avoiding strong winds or waterlogging.

1.2 Hanging Bag Cultivation Mode: Adopt a three-dimensional bag-hanging method and equip with sunshade nets.

Figure 3. Open-field cultivation mode (left) and hanging bag cultivation mode (right)

2. Key Steps for Black Fungus Cultivation

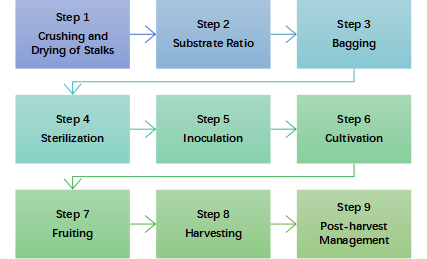

The following steps outline the complete production process for black fungus.(see Figure 4).

Figure 4.

Step 1. Crushing and Drying of Stems

Harvest fresh, disease-free and mold-free cassava stems, dry them in the sun, and then crush them into particles sized 5–12 mm × 5–12 mm. Dry the stalk chips on sunny days, and collect them promptly if it rains to prevent them from getting damp. Once fully dried, gather the chips, put them into bags, and store them in a dry place for later use (see Figure 5).

Figure 5. Stem crushing and drying

Step 2. Substrate Ratio

The ratio of the growing medium is cassava stems to wood chips = 5:4. You also need to add 8% bran, 1% lime, and 1% gypsum powder. First, mix all these ingredients well. Then pre-wet the mixture 12 to 24 hours ahead of time. Add water little by little, until when you squeeze the material in your hand, it clumps together without breaking apart or dripping water. The overall ratio of material to water should be 1:1.3 to 1.7. Next, sift the mixed medium to get rid of any impurities. Pile it up, cover and seal it for 1 to 2 hours, and then put it into bags (see Figure 6).

Figure 6. Substrate proportioning

Step 3. Bagging

Put the mixed substrate prepared in step 2.2 into special bags for growing edible fungi. Press it down gently and spread it evenly inside the bags. Make sure the medium is tightly packed and well-combined, which helps the fungi to colonize and grow better. Then seal the bag openings with sterile cotton plugs (see Figure 7).

Figure 7. Bagging

Step 4. Sterilization

Wrap the cultivation bags up tightly with a thick, airtight tarpaulin that can stand high temperatures. Tie the edges of the tarpaulin securely so that the temperature inside stays around 100℃. Then let them sterilize at normal pressure for 8 to 10 hours (see Figure 8).

Figure 8. Sterilization

Step 5. Inoculation

Once the sterilization is done, let the culture medium cool down to below 30℃. Then, in a sterile environment, take off the cotton plugs from the cultivation bags, inoculate the spawn into the bags quickly, and seal the bags right away. Before starting the inoculation work, the operators must disinfect their whole bodies thoroughly to keep the cultivation bags from getting contaminated (see Figure 9).

Figure 9. Inoculation

Step 6. Cultivation

Keep the cultivation bags in a dark place for cultivation. Maintain the air humidity at around 60–70%, make sure to ventilate the area regularly, and keep the temperature of the mushroom bags steady at 22–25℃ all the time (see Figure 10).

Figure 10. Cultivation

Step 7. Fruiting

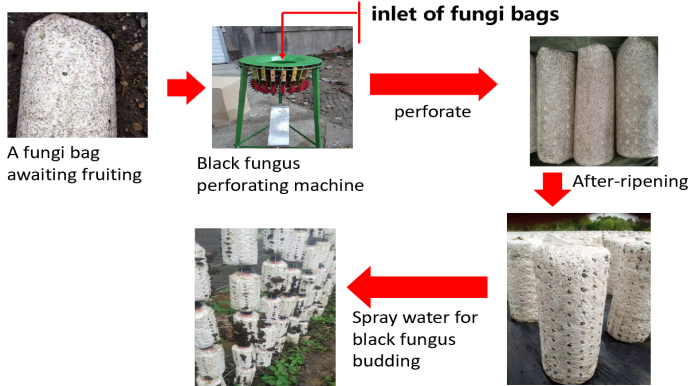

Disinfect the surface of the sticks and the punching tools with a 2%–5% potassium permanganate solution. Usually, make small cuts on the bags in the shapes of "I", "Y" or "O". Then put the bags in a spot with indirect light and air them out every day for 5 to 7 days. This will let the mycelium inside the bags grow over and seal these fruiting holes (see Figure 11).

Figure 11. Fruiting

Step 8. Harvesting

Do not spray any water on the black fungusone day before harvesting. After you pick the black fungus, clear out the leftover black fungus roots, diseased fungus, and dead ones from the surface of the substrate right away. This keeps them from rotting and letting harmful fungi contaminate the rest. Also, hold off on spraying water for another 2 to 3 days after harvesting. This gives the mycelium time to recover and grow again (see Figure 12).

Figure 12. Harvesting

Step 9. Post-harvest Management

When drying the black fungus, spread them out evenly on drying mats, reed mats or nylon nets. Choose sunny days to dry them for 1 to 2 days until they are completely dry.

Do not flip the black fungus over repeatedly before they are dried, even if you want to increase the area exposed to sunlight (see Figure 13).

Figure 13. Natural drying

Analysis of Key Links

1. Mycelium Growth Management

Start checking the cultivation bags for mold contamination 3 to 4 days after inoculation. Do the first pile turning 7 to 8 days later, then turn the piles once every 7 days after that.

Each time you turn the piles, check carefully and remove any contaminated bags right away for proper disposal. Ventilate the growing area in the morning and evening every day and keep the air humidity at around 60–70%. Let the mycelium grow for 25–30 days until it fully spreads through the bags. Then let the mycelium "ripen" for another 3–5 days before you start the fruiting management stage.

2. Field Management

Once you move the cultivation bags to the field, hang them up in the black fungus shed as required as soon as you can. If you cannot hang them right away, keep them out of direct sunlight. After hanging the bags, check the temperature and humidity inside the shed frequently. The temperature should stay around 28℃, and the humidity needs to be at least 80%. On hot days, remember to turn on the misting equipment to add moisture and keep the humidity stable. If the local temperature and humidity are just right, you can start regular watering to encourage fruiting 4 to 5 days later. This is usually when you spot small black dots at the cut openings of the bags.

3. Harvesting Standards

Harvest the black fungus in good time. You should pick them when the ear slices have mostly spread out, but their edges are still curled inward and have not fully flattened or turned thin yet. Timely harvesting is super important here. If you wait too long, it will mess up the growth of the next batch of ear buds and the development of new ear slices.

4. Harvesting Methods

Don’t water the black fungus one day before harvesting. This prevents too much moisture from touching the fungus, which would easily lead to rot. To harvest, use your thumb and index finger to quickly pinch the ear slices that meet the picking criteria. Pull them off gently, then let go to drop the slices into a plastic basket. Repeat this until you have picked all the ready-to-harvest ear slices.Do not rub the cultivation bags randomly with your hands. This could damage the bags or knock off the new ear buds that are just starting to grow.

5. Post-harvest Management

Place the freshly harvested black fungus in an oven set to 55℃ and dry them until they are completely crisp. This usually takes around 6 hours. Remember to turn the fungus over every 2 to 3 hours while it is drying. After harvesting, start watering the cultivation bags again as normal, and keep doing this until the next harvest. Repeat this cycle of harvesting and watering until the substrate inside the bags pulls away from the bag walls. That is the sign that the black fungus has stopped growing and the cycle is done.

Applicability

1. Effectiveness

This method is ideal for promotion and use in all the tropical countries and other regions where cassava is grown.

2. Environmental Conditions such as Climate and Soil

Black fungus grows well at temperatures between 15–28℃. The best temperature for mycelium to develop is 20–25℃, while the fruiting bodies need a temperature range of 22–28℃ to form properly.

In tropical regions, you should take steps like shading the growing area and improving ventilation to keep the fungus from being exposed to direct high heat. Note that temperatures over 35℃ will slow down or stop its growth entirely.

For humidity: the culture medium needs to have a moisture content of 60–65%. When the fruiting bodies are growing, the air humidity should be kept at 85–95%.

In tropical areas with high humidity, make sure to set up good drainage. This prevents water from pooling around the cultivation bags and stops the ears from rotting due to excess moisture trapped inside the substrate.

Risks and Benefits

1. Costs and Benefits

Each black fungus bag yields an average of close to 40 grams of dried black fungus. At the market price of 12.88 USD per kilogram, 10,000 such bags can bring in a gross revenue of 5152 USD.These data on economic benefits are based on the market prices in China and are for reference only. The actual price shall prevail according to the local market in the current year.

2. Risks and Measures

2.1 Main Risks

Crop prices tend to fluctuate a lot because of market changes. If you cannotsell all the products, it will have a big negative impact on your profits. What is more, extreme weather like seasonal droughts and heavy rains can easily cause the yields to drop sharply.

2.2 Measures

Sign contract farming agreements to secure reliable sales channels for your agricultural products.

Practical Cases

Good results have been achieved in cultivating edible fungi using cassava stems as substrate in Danzhou City and Baisha County, Hainan Province, China.(see Figure 14).

Figure 14. Open-field cultivation mode (Left) and hanging bag cultivation mode(Right)

Conclusion

As an abundant resource, there are several advantages for planting black fungus by cassava stems. First, it fixes the problem of not having enough raw materials to grow the fungus. Second, in places where cassava is grown, cassava stems are easier and faster to get than wood, reducing the cost of growing black fungus a lot. In addition, it stops discarded cassava stems from polluting the environment.

Moreover, in tropical areas with lots of under forest space, you can use a “mixed three-dimensional growing method” under the trees. This way, growing fungus does not conflict with taking care of the trees or with harvesting wood. They actually help each other. And after growing the fungus, the leftover material is great for the trees. It gives them plenty of nutrients. This method not only keeps the forest humid and helps trees grow better but also makes the local industry structure more balanced and gives the local economy a nice boost.

Supporting institutions:

· Tropical Crops Genetic Resources Institute, Chinese Academy of Tropical Agricultural Sciences

· Chinese Cassava Agro-technology Research System

Contact information: E-mail: liminglin@catas.cn

Category

Black Fungus Cultivation Technology with Cassava stems as Material

Contributor

Black Fungus Cultivation Technology with Cassava stems as Material

Country

Black Fungus Cultivation Technology with Cassava stems as Material