Technical Background

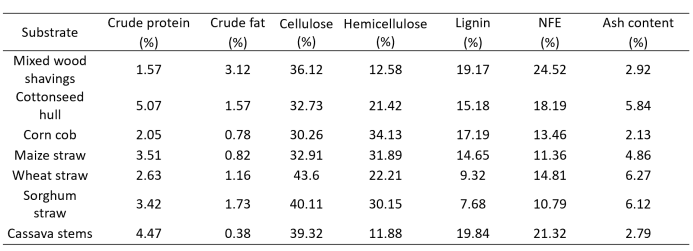

Cassava stems are a major by-product of the industry, but they are often just burned or thrown away, which pollutes the environment and wastes a valuable resource. Research shows these stems are actually great for growing mushrooms. They are rich in protein (4.47%) and cellulose (39.32%)—levels that match or even exceed common materials like wood chips and cottonseed hulls. When crushed, they hold water and allow air flow better than wood chips, making them an excellent base for cultivating mushrooms (see Table 1).

Using cassava stems to grow edible mushrooms solves several problems at the same time. It provides a sustainable raw material for the mushroom industry, reduces the environmental pollution caused by burning or discarding these stems, and significantly lowers production costs due to their abundance and low price. This method has already seen some adoption and application in China. Most edible fungi can be cultivated using cassava stems. In this paper, the common oyster mushroom is selected as a typical example for detailed illustration.

Table 1. Component Analysis of Cassava Stem

Implementation Measures

1. Preparation Stage

1.1 Site Preparation

The site should be selected in an area with high terrain, flat and open space, good ventilation, convenient drainage, and a clean surrounding environment. It should be far away from pollution sources such as factories and garbage disposal sites to avoid adverse effects of waste gas, wastewater, and waste residues on mushroom growth. If indoor balconies, terraces, etc., are chosen as planting sites, sufficient ventilation, adequate light, and good drainage must be ensured.

Before planting, the site should be thoroughly disinfected to eliminate pathogenic bacteria and weed seeds. According to the site size and the number of cultivation bags, corresponding shelves should be built to place the cultivation bags or rods, as shown in figure 1.

Figure 1. mushroom fruiting rack

However, growing oyster mushrooms on shelves is not absolutely better than growing them on the ground. Which method is superior mainly depends on your planting scale, site conditions and management needs. For large-scale, standardized cultivation, shelf growing has more obvious overall advantages: it allows three-dimensional use of space, increasing the site utilization rate by 2 to 3 times. What is more, each layer of mushroom bags can get more uniform ventilation and light, which reduces the risk of misshapen mushrooms and mixed fungus contamination. Meanwhile, management tasks like picking, watering and disinfection become much more convenient, and it also effectively cuts down the infestation of ground-borne diseases and pests. On the contrary, ground planting is more practical for small-scale, low-cost home cultivation. It requires no shelf-building, thus saving cost and being easier to operate. As long as you take key measures such as elevating the mushroom bags, ensuring proper ventilation and carrying out thorough disinfection, you can basically guarantee a good yield and quality of the mushrooms

1.2 Greenhouse Construction

Build the greenhouse in a leeward and sunny area, preferably in an east-west direction. The greenhouse roof should be firmly framed with bamboo poles, covered with plastic film, and topped with straw curtains. Ventilation openings should be set inside the mushroom house, and the distribution of these openings should be reasonable to effectively regulate air circulation in the mushroom house.

Building a mushroom fruiting room is key to the standardized and efficient cultivation of mushrooms. It not only precisely controls the temperature, humidity and other growth conditions to ensure the healthy development of mushroom fruit bodies but also breaks seasonal limitations to achieve year-round stable production. In addition, the enclosed space makes disinfection easier, effectively reducing the risks of pests and harmful contaminants. It also allows for shelf cultivation, which boosts space utilization, facilitates centralized management and harvesting, and thus improves the commercial value and economic benefits of mushroom products, as shown in Figure 2.

Figure 2. Construction of Mushroom Fruiting House

2. Key Stepsfor Oyster Mushroom Cultivation

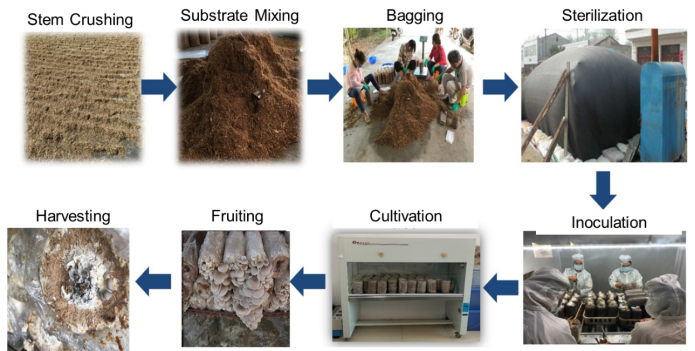

The following steps outline the standard procedure for preparing the substrate, inoculating, cultivating, and harvesting oyster mushrooms using cassava stems, as shown in Figure 3.

Figure 3. Operation Process

Step 1. Crushing and drying of stem

Harvest fresh cassava stem without diseases, pests, or mildew, dry them in the sun, and crush them into particles of 5~12mm×5~12mm. Dry the stem chips in sunny weather; in case of rain, collect them promptly to avoid getting wet. After drying, collect and bag the chips for later use in a dry condition.

Step2. Substrate Ratio

The optimal substrate ratio is 40-70% cassava stem chips, 10-20% wood chips, 10-15% bran, 1% gypsum powder, and 1-2% lime. After mixing the formula evenly, pre-wet it 12~24 hours in advance. Add water in batches until the material holds together without falling apart or dripping when squeezed by hand. The total material-to-water ratio is 1:1.3~1.7, and the pH value is 7~8. Sieve the mixed culture medium to remove impurities; after stirring, pile and seal the medium for 1~2 hours before bagging.

Step 3. Bagging

Fill the mixed substrate from Step 2.2 into special cultivation bags, compact and distribute the substrate evenly. Ensure the culture medium is in close contact to facilitate colonization and growth and seal the bag mouth with sterile cotton plugs.

Step 4. Sterilization

Cover the cultivation bags with airtight, high-temperature-resistant tarpaulin, and tie the edges tightly to ensure the temperature inside the tarpaulin can be maintained at around 100℃. Sterilize under normal pressure for 8~10 hours.

Step 5. Inoculation

After sterilization, cool the culture medium to below 30℃. Under sterile conditions, open the plugs of the culture bags, inoculate quickly, and then seal the bags. Operators must disinfect their entire bodies before inoculation to avoid contaminating the cultivation bags.

Step 6. Cultivation

Cultivate in dark light, control the relative air humidity at approximately 60-70%, ventilate regularly, and maintain the temperature of the cultivation bags at 22-25℃ at all times.

Step 7. Mushroom Fruiting

Transfer the cultivation bags after post-ripening cultivation to the fruiting site. Use a multi-layer shelf-type cultivation shed and arrange the bags in a shelf-type manner for fruiting. Maintain the environmental temperature in the fruiting shed at 18-28℃, with a temperature difference of 6-10℃ being optimal.

Maintain air humidity by aerial spraying; meanwhile, spray water on the ground and surrounding walls, avoiding spraying water directly on the bag mouths to prevent water accumulation on the mushrooms. Keep the relative air humidity in the mushroom shed at approximately 80-90%. Increase ventilation to keep the indoor air fresh and ensure a certain amount of scattered light, which is conducive to the formation of primordia.

Step 8. Harvesting

Harvest promptly when the mushroom caps are basically flat, and the spores have not yet been ejected. Stop spraying water 1 day before harvesting. After harvesting, promptly remove the residual mushroom roots, diseased mushrooms, and dead mushrooms from the substrate surface to prevent rot and contamination by miscellaneous fungi. Meanwhile, stop spraying water for 2-3 days to allow the mycelium to recover growth.

Analysis of Key Links

1. Mycelium Growth Management

Start checking for miscellaneous fungus contamination 3-4 days after inoculation. Conduct the first pile turning 7-8 days later and then turn the piles every 7 days thereafter. During each check, remove contaminated cultivation bags and dispose of them promptly.

Ventilate the cultivation area once in the morning and once in the evening to maintain an air humidity of 60-70%. Cultivate for 25-30 days until the mycelium fully colonizes the cultivation bags, then conduct post-ripening cultivation for 3-5 days before proceeding with fruiting management.

2. Mushroom Fruiting Management

Roll up the straw curtains for ventilation in the morning and evening; spray water appropriately at noon when the temperature is relatively high.

3. Harvesting Standards

After harvesting, promptly clean the fruiting surface and remove dead or rotten mushrooms in a timely manner. For oyster mushroom grown in the shed, 2-3 flushes of mushrooms are generally appropriate.

Applicability

1. Effectiveness

This technology is suitable for promotion and application in cassava-growing regions such as tropical countries around the world.

2. Environmental Conditions

Maintain a temperature of 25-30℃ during the mycelium growth period and a stable temperature of 13-20℃ during the fruiting period. Keep the humidity at approximately 70% during the cultivation period and 85%-95% during the fruiting period. Direct sunlight should be avoided.

Risks and Benefits

1. Risks

Crop prices fluctuate significantly due to market influences; unsold products will greatly reduce profits. Extreme weather such as seasonal droughts and heavy rains may easily lead to reduced yields.

2. Benefits

Each oyster mushroom bag yields an average of about 700 grams of fresh oyster mushrooms. At the wholesale market price of 0.32 USD per 500 grams, 10,000 such bags can bring in a revenue of approximately 4,480 USD in the Chinese market. These data on economic benefits are based on the market prices and are for reference only. The actual price shall prevail according to the local market in the current year.

Practical Cases

In Danzhou City and Baisha County, Hainan Province, good results have been achieved in cultivating oyster mushroom using cassava stems as the substrate. (see Figure 4)

Figure 4. Cultivation of oyster mushroom

Conclusion

Using cassava stems to cultivateoyster mushroom reduces the environmental pollution caused by the massive disposal or incineration of cassava stems. Meanwhile, compared with wood, cassava stems are more abundant and cheaper, thus significantly lowering the production costs of oyster mushroom. In addition, relevant studies have confirmed that cassava stems can replace sawdust and cottonseed hulls to successfully grow edible mushrooms such as enoki mushrooms and king oyster mushrooms. In summary, cassava stems boast broad development prospects. With rational utilization, they can not only reduce environmental pollution from discarded stems, but also drive the development of related industries, solve the employment problems of many farmers, create remarkable economic benefits, and realize circular and sustainable development.

Supporting institutions:

· Tropical Crops Genetic Resources Institute, Chinese Academy of Tropical Agricultural Sciences

· Chinese Cassava Agro-technology Research System

Contact information: E-mail: liminglin@catas.cn

Category

Growing oyster mushrooms by cassava stems

Contributor

Growing oyster mushrooms by cassava stems

Country

Growing oyster mushrooms by cassava stems