- Do you have experience about telling the grain moisture content if there is no proper tool?

PHLM & Food Systems

To determine grain moisture content without proper tools, you can use sensory methods. To understand whether the grain is at the moisture level for safe storage when you don't have the moisture meter, please use your teeth. When dried rice is bitten with teeth, the sound is crisp travelled through the teeth and the husks separate. When dried corn is bitten with teeth, the sound is clear and crisp causing vibration, and the cutting surface is smooth. When dried wheat is bitten with teeth, the sound is crisp and cutting surface is neat.

- For farmers in country like Liberia, kindly recommend if you are aware of some affordable biological pests and insects control materials that can be adopted by them in the terrain since most of them don't have asset to getting some of the chemicals being presented here?

PHLM & Food Systems

Common methods used by farmers for pest prevention in stored grains:

(1) Using dried leaves of willow, chinaberry, houttuynia cordata, or mugwort: mix these dried leaves, crush them into powder, put it in the raw grain layer by layer, and stir the mixture. Typically, 2 to 3 kilograms of this mixed powder are used for 100 kilograms of grain. Compared with other layers, a bit more powders will be on the top layer. It is highly effective at repelling external pests.

(2) Using kelp: mix dry kelp with the grains. After one week, the kelp absorbs water from the grains and can kill mites and moth pests. The kelp can be reused after drying again, which will not affect its edible value.

- Why the larval stage is considered as the most harmful stage?

PHLM & Food Systems

The larval stage is the most harmful because the quantity of pests is high during this stage, and they grow quickly and consume a lot. Some pests can burrow into the grains to cause more severe damage.

- How long is the shelf life of grain in hot Areas like Kenya?

PHLM & Food Systems

In hot regions like Kenya, grains are prone to pest infestations. It is recommended that the storage period for paddy and corn in hot areas be 1 to 1.5 years, and for wheat, 1 to 2 years.

- About the exposure of Grains in direct sunlight. Is there any way to prevent direct sunlight some areas in Kenya, normally above 40°C?

PHLM & Food Systems

When drying paddy is under high temperatures (over 40°C), it's advisable to spread the paddy bulk thicker and turn it over frequently to prevent prolonged exposure to sunlight with high temperatures. Additionally, once the paddy is dried, it should be stored asap to avoid overexposure and excessive dryness.

- Does the water ratio vary from location to location or is it a standard (wheat 12.5%, paddy 13.5%, corn 13-14%)?

PHLM & Food Systems

The Chinese moisture standard is the highest moisture content of grain to ensure the safe grain storage in all regions during the summertime. There is a significant climatic difference between southern and northern regions. The northeast region is dry and cold, whereas the southern region is hot and humid. Therefore, in the northeast region, due to lower temperatures and drier conditions, which are suitable for grain storage, the moisture standard cannot be such strict to ensure the safe storage of grains.

- Do the smallholders use threshers and shellers? If not, what kind of equipment do they use for these activities?

PHLM & Food Systems

In rural China, smallholders use threshers or combine harvesters for separating straw and grain kernels.

Traditional Thresher Mechanical Thresher Combine Harvester

- A series of questions about the Small Steel Silo

PHLM & Food Systems

1. What is the maximum capacity of one small steel silo?

The maximum capacity is 1.4 tons or 1.5 tons. The value can be expanded, but if it is more than 1.5 tons, the silo will be under the higher pressure. Extrusion and deformation of the silo are caused by too many grains.

2. How efficient is the air tightness of the silo?

There are three layers in the small steel silo. For its air tightness, it is still at the average level rather than the best. The quality of grain storage will be better only if all pests are killed. There will be less pests if silos meet the standard. In China, there are many kinds of protectants used for grain storage to prevent pests.

3. What is the specific regulation or standard for the temperature inside the silo?

Generally speaking, it is recommended that the temperature should not exceed 30°C. Without the specific standard in China, China Grain Reserves Group has its own enterprise standard. The temperature inside the silo can be detected and monitored through temperature measurement instrument. The temperature measurement instrument on the market in China could be installed in the silo to measure the temperature inside.

4. How can the temperature be regulated in steel silos?

Temperature will definitely affect the quality of stored grain. It is important to monitor the temperature. In China, we suggest all smallholders install steel silos indoors without direct exposure to the sunlight, which could reduce the negative impact on the stored grain from the environment. The temperature where people live is suitable for the grain storage. There is the small instrument of grain temperature measurement in China, which could be shared with other countries. It might be adaptable in the small steel silo.

The customized resistance thermometer rod measures grain temperature to avoid overheating.

5. How much does the silo cost? How affordable are these storage facilities in Africa like Ethiopia?

The market price of one small steel silo is about CNY400-500 (USD56-70) in China, which is equal to one farmer's two-day income. The farmer can afford the cost, which is the reason why this silo is popular in China. In African countries, the cost will be mainly affected by the price of the steel, artificial processing, transportation, and many other factors. In China, it is suggested that the silos should be produced and processed locally through storage programs rather than long-distance transportation. There are many small-scaled processing plants joined by smallholders. They usually conduct farming activities and engage in silo processing and purchase in the off season.

6. Are there any other materials used to store grains which are available in rural areas in African countries such as Kenya?

In the special program of smallholder grain storage in China, the silo material was chosen according to

the national standard; therefore, farmers used the same small steel silo. After the program, there are different types of silos made of various materials in the market. For instance, there are 0.3 mm and 0.4 mm thick pre-painted steel plate. There are also zinc plate called white steel plate. There are silos made of different materials, the cheapest one of which costs only CNY100 (around USD15). Therefore, other local materials can be used to reduce the amount of steel to produce the silo. For instance, the stainless steel can be replaced by zinc or pure original steel. In addition, PVC soft silo (as shown in the picture) is cheaper for grain storage, which is popular among farmers in arid regions such as Henan Province and Hubei Province in China.

the national standard; therefore, farmers used the same small steel silo. After the program, there are different types of silos made of various materials in the market. For instance, there are 0.3 mm and 0.4 mm thick pre-painted steel plate. There are also zinc plate called white steel plate. There are silos made of different materials, the cheapest one of which costs only CNY100 (around USD15). Therefore, other local materials can be used to reduce the amount of steel to produce the silo. For instance, the stainless steel can be replaced by zinc or pure original steel. In addition, PVC soft silo (as shown in the picture) is cheaper for grain storage, which is popular among farmers in arid regions such as Henan Province and Hubei Province in China.7. Can examples of smallholders' storage facilities used in African country like Kenya or maybe other African countries be shown?

Chinese smallholders use the small steel silo, which also could be applicable to African countries. Smallholders in Africa could also use this storage equipment because the cost of this equipment is relatively low, as well as the operational management cost. If smallholders in Africa are interested in this practice, the processing technology of small steel silos for smallholders could be further shared, which will be beneficial for local promotion and application of small steel silos for smallholders.

8. How can China help to have small scale farmers in Zambia access the silos at a cheap price? What are more details about the technology?

Firstly, it is suggested to produce small steel silos locally in Zambia or to allow some smallholders to use small steel silos as the pilot. It is possible to provide further guidance for local production and utilization of the small steel silo if the pilot is successful. The technical video on the production and utilization of small steel silos for smallholders could also be made for any further needs, which can be shared with smallholders in Zambia.

9. What are the advantages and disadvantages of the approach that local government and households co-share the cost of this green storage equipment, if it is adopted by African countries?

I think the silo could be applicable to all the other countries. The key factor is the enough local steel plate. The price of steel plate in Africa is more than CNY10,000 (about USD1,500) per ton, twice price in China, and even higher. It affects the local government's decision on the policy of sharing the cost of grain storage equipment.

10. In some places with very high temperature, is it possible to make any modification to the steel silo?

Some modifications for steel silo could be made. The small steel silo is mainly used by smallholders to store grains indoor.

11. Can the silos manufactured with PVC materials be produced bigger than the presented volume?

Theoretically speaking it is possible to make it bigger, but so far, we have no consideration in this aspect.

12. For smallholders who may not have the means of buying a temperature regulator, can the silo be perforated, and can the perforated areas help prevent pest infestation?

In China, there are many stored-grain protectant used for grain storage, which can also prevent pests in grains.

- Can more details on bag drying be given?

PHLM & Food Systems

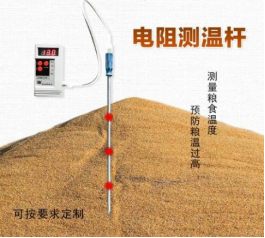

The In-bag Drying is a new type of drying modes. As each bag is one drying unit, the grain to be dried is placed in the designed drying bag, which is on a designed base. The hot air is transported into the base by a fan through an air duct to dry the grain in the bag. The In-Bag Drying system mainly consists of grain bags, air ducts, bases (including movable pull rods), heat pumps, fans, lifting and conveying equipment (as shown in the figure).

The In-bag drying is very flexible when the drying capacity is measured in bags. The weight of grain bag and air volume can be adjusted correspondingly according to the requirements of grain moisture and grain varieties. The simultaneous drying is possible for grains with different varieties, moisture contents and drying requirements. This flexible drying mode is suitable for the post-harvest centralized and energy-saving drying needs of small and medium-scaled farmers in China.

Fig. In-bag Drying Equipment

- What are the definitions of different scale of smallholders in terms of land size, production and grain storage duration?

PHLM & Food Systems

Normally, one farmer whose grain production is lower than 10 tons is defined as the smallholder. One or few steel silos will be enough for one smallholder. It is not recommendable for one smallholder to store a lot of grains at home, while the household grain storage for one-year consumption could be enough. Larger grain storage amount, higher the loss. Less grain storage places, lower the loss. Therefore, during the post-harvest season each year, the national government always encourages smallholders to send their grains to the national reserves to be stored. Before 2005, individual grain storage accounted for 50% of total grain output, but now the percentage is becoming lower, 30%-40%, which indicates the amount of smallholders’ grain storage is smaller. The large-scaled farmers normally have 3-60 hectares of arable lands. For this group, it is also suggested that their grains should be processed by themselves or just sold to the national government. It is unnecessary for them to pay extra fee to build grain storage facilities or concern the grain storage when they are not professional technicians and usually meet the challenge of the grain loss. Therefore, in China normally it is suggested that farmers sell grains to the food processing companies for the concentrated processing.