After harvest, corn typically has a relatively high moisture content. Improper storage conditions can easily lead to heating and mold growth, which will affect the quality of the corn. This underscores the critical need for proper storage infrastructure to maintain corn quality and ensure safe, efficient storage. Professor Yan Xiaoping, Chief Technical Officer and Researcher at the China Grain Storage Chengdu Storage Research Institute, introduces different types of grain storage equipment, their key structural features, and installation guidelines to optimize storage conditions.

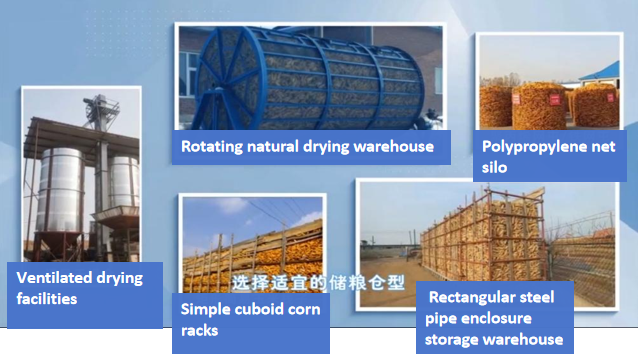

Corn can be stored in simple structures like baskets, polypropylene net silos, or steel-framed warehouses with ventilation channels to improve air circulation. Storage sites should be located on elevated, well-ventilated terrain, away from pollution sources. When handling corn, conveyors or small loaders are recommended to prevent damage to the storage facility and ensure safety.

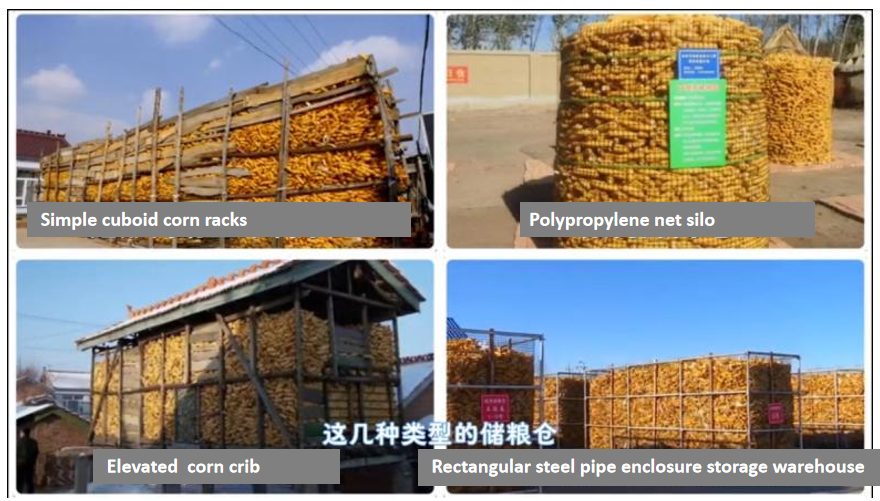

1. Types of Grain Storage Equipments

• If the corn yield is not large, one can use steel pipes and wooden sticks as a frame, and use steel wire, wire mesh, bamboo, or wooden boards as enclosures to construct a rectangular corn storage basket.

Types of Grain Storage Warehouses

• Alternatively, one may purchase a pre-assembled corn ear storage warehouse of similar design. This type of storage warehouse is generally about 6 meters long, 1.5 meters wide, with a storage height of about 2 meters, and can accommodate approximately 13 tons of wet corn—meeting the yield needs of a ten-mu (equivalent to 0.67 hectares) harvest.

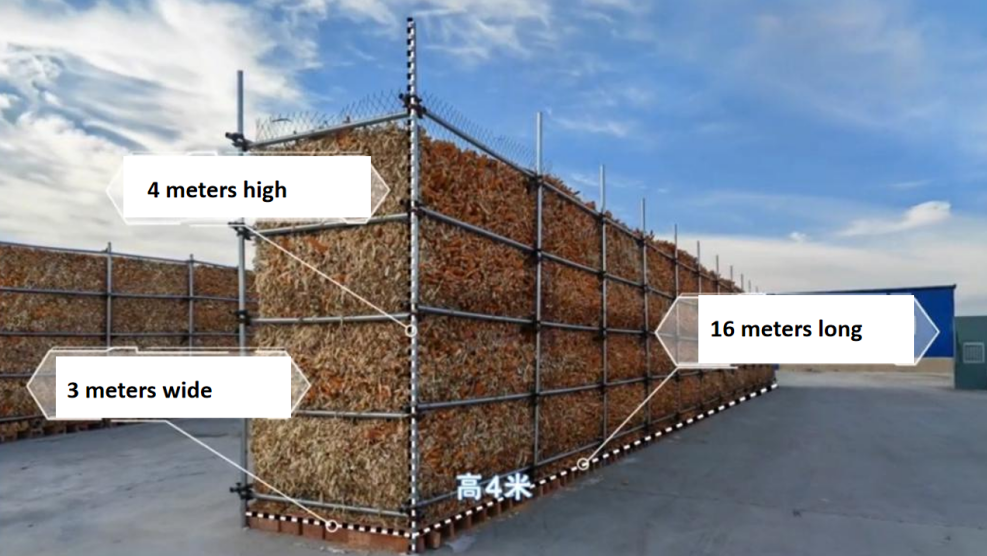

• If a larger quantity of corn is harvested, this type of warehouse can be adopted: 16 meters long, 3 meters wide, and 4 meters high. The interior should include ventilation channels and pipes to enhance natural ventilation and dehumidification. The base of these storage warehouses must be constructed solidly.

Modular Steel Frame Warehouse

Ventilation channels and pipes

2. Installation Instructions

Located away from pollution sources, on elevated terrain with firm ground, good ventilation, and smooth drainage—approximately 2 meters away from walls or other structures.

Before loading corn ears into the storage warehouse, husks and other impurities should be removed, and corn ears that are severely affected by insect damage or mold should be stored separately.

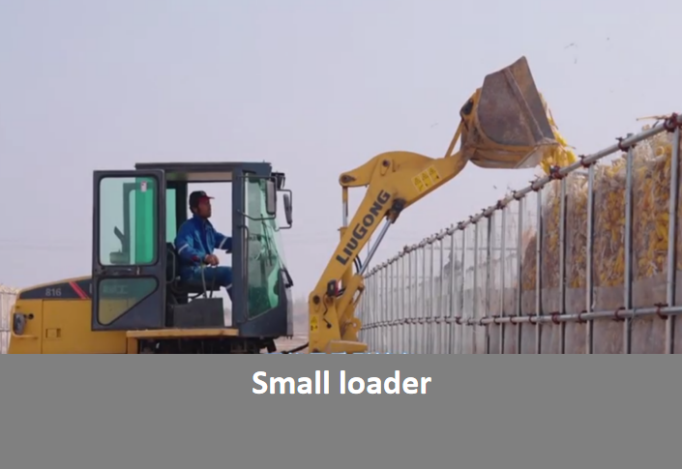

When moving corn ears in and out of the warehouse, a conveyor or small loader may be used. Heavy loaders should not be employed to shovel large quantities of corn ears at once, as this may damage the warehouse and lead to safety incidents.

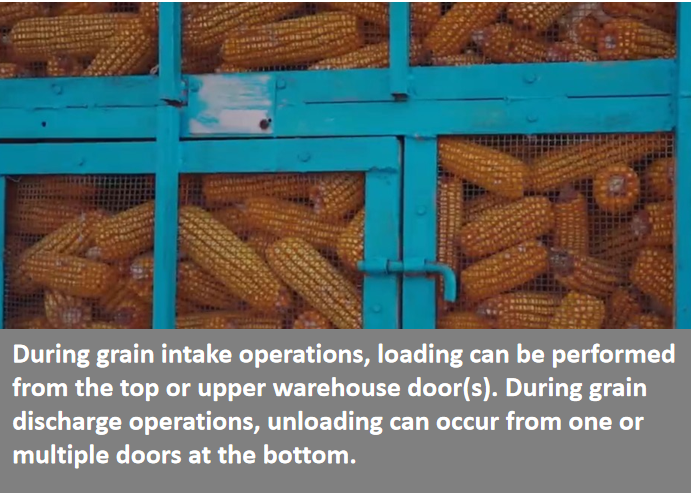

During grain intake operations, loading can be performed from the top or upper warehouse door(s). During grain discharge operations, unloading can occur from one or multiple doors at the bottom. Operators should monitor the shifting center of gravity of the grain pile inside the warehouse and adjust the positions for loading and unloading promptly to prevent imbalance and potential collapse.

Besides, if the moisture content of corn ears is high and rapid dehumidification is needed, a rotating natural drying warehouse can be utilized.

Farmers are recommended to select the appropriate type of storage warehouse based on their actual conditions to ensure optimal grain storage quality.

Reference:

The Expert Talk video series produced by the National Food and Strategic Reserves Administration of China

Corn Storage Equipment Types and Applicability

Related Links:

1. Wheat Mold Prevention, Control, and Loss Reduction Techniques

3. Corn Storage in Open-air Structures: Common Methods, Technical Requirements, and Considerations

4. Standards for Grain Conservation and Loss Reduction Across Different Circulation Stages

5. Innovation-driven Approaches to Post-harvest Grain Conservation and Loss Reduction

6. Ensuring Quality and Reducing Losses: Rice Harvesting and Storage Techniques in China

Category

Technical Solution

Contributor

Corn Storage Equipment Types and Applicability

Country

Technical Solution