Food security is vital to a country’s economy and people's livelihood. As one of China’s staple grains, rice requires careful post-harvest handling to maintain quality and minimize losses. Zhang Zhongjie, director of the Institute of Grain Storage and Logistics at the Academy of National Food and Strategic Reserves Administration, explains key techniques for achieving these goals, covering the processes of harvesting and storage.

1. China’s National Food Security Strategy

The Chinese central government places a high priority on food security. It has established a national strategy on food security featuring self-sufficiency based on domestic grain production, guaranteed food production capacity, moderate imports, and technological support. This food security policy aims at ensuring basic self-sufficiency of grain and absolute security of staple food.

China's annual grain production has exceeded 650 million metric tons for years, with rice accounting for nearly one-third of it. Given that rice contributes around 70% of the nation’s staple food consumption, ensuring its quality and safety throughout the entire value chain is essential. This includes seed systems, cultivation, harvesting, procurement, storage, processing, and sales. Ensuring safety at each step is vital to maintaining national food sovereignty and reducing post-harvest losses.

2. Best Practices in Rice Harvesting and Immediate Post-harvest Handling

In recent years, grain industry professionals have been actively exploring and strengthening technological innovation, aiming to minimize both quantitative and qualitative losses after rice harvesting. The keys are:

2.1 Seizing the golden harvesting period

Regarding the optimal timing for rice harvesting, timely harvesting is crucial for minimizing loss. Theoretically, the best harvest time for rice is when it reaches full maturity. Harvesting too early or too late can lead to losses. If harvested too early, the rice grains are not fully developed, resulting in a higher proportion of immature (green and shriveled) kernels. If harvested too late, the incidence of "white belly," one of the dominant types of chalkiness" of rice increases, which lowers the head rice rates during subsequent processing. Head rice normally includes broken kernels that are 75-80% of the whole kernel. High head rice yield is one of the most important criteria for measuring milled rice quality.

Additionally, close attention must be paid to regional weather changes around the harvest period—particularly to avoid adverse weather events such as thunderstorms and strong winds, which can negatively impact rice production. The harvest window should be selected based on the maturity status of the rice and in coordination with regional weather forecasts and warnings.

2.2 Intelligent drying for quality preservation

2.2.1 Importance of timely drying

With regard to the timely drying of rice, freshly harvested rice grains contain high moisture levels and should ideally be dried to a safe moisture content within 48 hours. This is crucial to prevent issues such as germination, insect infestation, heating, mold growth, or even rotting during storage.

2.2.2 Drying technologies

Rice drying equipment

Drying methods and equipment are adapted to regional climates. For example, during July and August, when early-season rice is harvested in southern China, air-source heat pump drying technology is commonly used. This technology extracts low-grade thermal energy from hot and humid ambient air and upgrades it to high-grade thermal air at 65–70°C. The resulting clean and efficient heat source is used to dry moist grains through temperature-controlled, cyclic processes, reducing their moisture content to safe levels. This approach ensures environmental sustainability, conserves energy, and preserves grain quality.

2.2.3 Infrastructure development

In recent years, China’s relevant national authorities have established more than 5,500 post-harvest grain service centres across the country. These centres offer services such as cleaning, drying, storage, processing and sales, effectively reducing post-harvest losses and helping farmers achieve higher yields and incomes.

3. Quality Preservation and Fresh Storage of Dried Paddy Grains

To ensure quality preservation and maintain the freshness of paddy grains across various storage conditions after drying them to safe moisture levels, the following sections outline the key measures implemented in China.

3.1 Basic principles of grain storage

China’s three major staple grains—paddy rice, wheat, and corn— are produced in large volumes and stored across diverse regions. As the country’s primary staple food, paddy rice is generally stored for 2-3 years. This includes both household storage and storage by grain storage enterprises.

Bulk grain bungalow warehouse: modern double-deck bungalow warehouse with naturally ventilated roof (Photo source: WGG)

Due to differences in storage regions, warehouse scale, and storage methods, different quality preservation techniques are applied. However, the fundamental principles are to ensure airtightness, heat insulation, and moisture-proofing of warehouses and storage containers; to control temperature and humidity of grain piles; and to prevent pest infestations and mold. These measures aim to delay the deterioration of grain quality during storage as much as possible, thereby providing high-quality raw grain for subsequent food and feed processing.

3.2 Support for household storage

For the majority of farmers storing their own grain with traditional storage containers such as household grain jars and tanks, relevant government departments have provided over 10 million sets of scientific grain storage warehouses nationwide. These include warehouses suitable for storing paddy and wheat, and steel combined grain warehouses for natural storage of corn ears suitable for large-scale farmers, with capacities ranging from 30 to 100 metric tons.

Leveraging initiatives such as the National Grain and Material Reserve Science and Technology Week and the Grain Science Promotion Village Tours, experts are organized to visit rural areas to conduct grain storage knowledge education, distribute storage kits and brochures to farmers, guide them on scientific grain storage, and help reduce grain loss.

3.3 State-owned storage systems

3.3.1 Capacity and technology

For the many state-owned grain storage enterprises, significant progress has been made in warehouses, facilities, equipment, and the development and application of new technologies. China currently has a well-maintained grain storage capacity of 700 million tons, and the application of storage technology is generally at a relatively advanced level worldwide, serving as a stabilizing force to ensure national food security.

These grain storage enterprises are committed to ensuring the quantity, quality, and safety of stored grain. They continuously develop and apply new grain storage technologies, processes, and equipment to support high-quality development of grain storage.

3.3.2 Core storage technologies

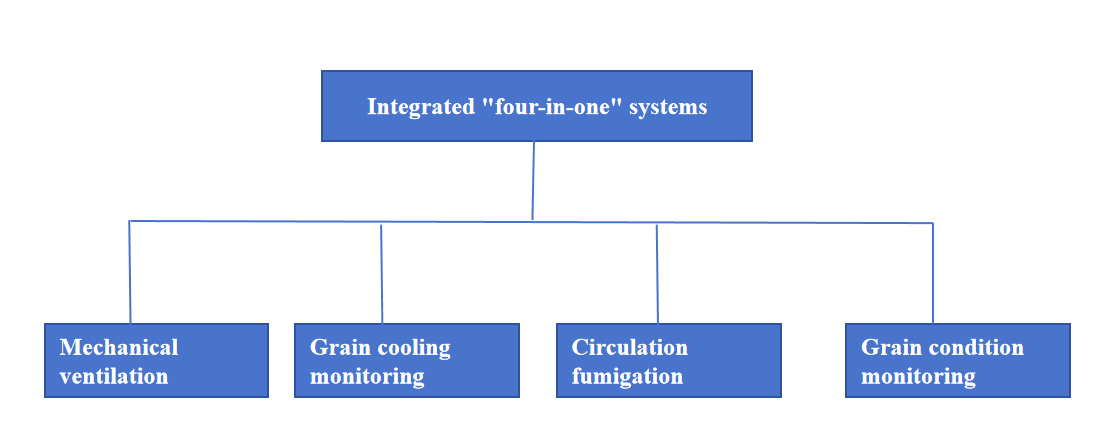

a.Integrated "four-in-one" systems

First, the state-owned grain storage facilities have widely adopted integrated "four-in-one" systems that combine mechanical ventilation, grain cooling, circulation fumigation, and grain condition monitoring. This technology won the First Prize of the State Scientific and Technological Progress Award in 2010 and has become standard in state-owned grain warehouses. Sensors are installed inside large grain piles to monitor basic parameters such as temperature and humidity in real time. Circulating fumigation equipment effectively controls pests and molds inside these piles. In addition, mechanical ventilation and grain cooling equipment prevent overheating and condensation in the piles. All of the above measures ensure stable quality and significantly reduce losses during storage.

b. Low and near-low temperature storage

Intelligent temperature control equipment (Photo source: WGG)

Second, grain storage in China spans seven major ecological zones. Differences exist in protective structures of warehouses and storage technology and equipment of grain piles due to varying climates, warehouse types, and grain varieties. Through the application of technologies such as rooftop photovoltaic solar power generation, radiation insulation, nano thermal insulation coatings, airtight and heat insulation materials, internal circulation temperature control, air-source heat pumps, intelligent ventilation, and dynamic analysis and warning of grain condition cloud maps, large grain piles can be effectively stored at low or near low temperatures in an environmentally friendly manner. Currently, the capacity for low-temperature and near low-temperature grain storage in China exceeds 200 million metric tons.

c. Integrated pest and mold control technologies

Third, pests and mold toxins are two major threats during grain storage. Controlled atmosphere storage technology involves filling airtight warehouses with nitrogen or carbon dioxide to create a low-oxygen environment in large grain piles cyclically. This slows grain quality deterioration while physically controlling storage pests and molds efficiently. This technology is currently applied in storage facilities nationwide in China with a total capacity exceeding 55 million metric tons.

The integration and innovative use of technologies, such as physical pest control methods like food-grade inert powders, light traps, and controlled atmosphere storage; biological control techniques using predatory mites and other natural enemies; biopesticides such as spinosad; and the combined use of ultraviolet light and plasma technologies to effectively reduce mold toxins, can significantly reduce chemical pesticide use and further improve large-scale green and low-carbon grain storage technology.

4. Supporting Measures for Loss Reduction

With the continuous development and application of post-harvest technologies and equipment for grain, the following additional measures are needed to ensure quality preservation and loss reduction after paddy rice is harvested.

4.1 Legal and policy framework

First, emphasizing policy guidance. In recent years, the state has issued a series of relevant laws and regulations, such as the "Anti-Food Waste Law of the People's Republic of China" and the "Grain Security Guarantee Law of the People's Republic of China," and has strengthened the assessment and accountability of grain security responsibilities shared by Party committees and governments. These measures provide a solid legal foundation for effectively carrying out grain-related work in the new era.

4.2 Technological integration and collaboration

Second, strengthening technological support. Relying on the National Engineering Research Center of Grain Storage and Logistics, the National Food and Strategic Reserves Administration has collaborated with research institutes, universities, and grain storage enterprises, and gradually built a five-dimensional integrated system of green grain storage technologies spanning storage and logistic sectors. This system includes: the application of new materials for storage facilities, efficient and environmentally friendly in-and-out storage processes, intelligent monitoring and early warning, integrated green pest and mold control, and scientific performance evaluation. To promote the adoption of advanced technologies within and outside the industry and reduce post-harvest losses of paddy rice, efforts are made through talent development and training, scientific innovation and demonstration projects, and science popularization and outreach, and enhanced international and domestic cooperation, and leveraging the advantages of internet platforms for information dissemination and technology transfer.

4.3 Standardization system

Third, enhancing the standards system. In recent years, the National Food and Strategic Reserves Administration has issued more than 10 standards related to paddy rice drying, storage, and quality testing methods, providing regulatory guidance for multiple stages of the post-harvest process. The continued development and revision of relevant enterprise, group, local, industry, and national standards have further strengthened the standardization system. This provides a benchmark for implementing technologies and management measures aimed at maintaining quality and reducing losses during paddy rice harvest and storage, and strongly supports the assurance of paddy rice quality and safety.

Reference:

The Expert Talk video series produced by the National Food and Strategic Reserves Administration of China

Ensuring Quality and Reducing Losses: Rice Harvesting and Storage Techniques in China

Related Links:

1. Corn Storage Equipment Types and Applicability

3. Corn Storage in Open-air Structures: Common Methods, Technical Requirements, and Considerations

4. Standards for Grain Conservation and Loss Reduction Across Different Circulation Stages

5. Innovation-driven Approaches to Post-harvest Grain Conservation and Loss Reduction

6. Wheat Mold Prevention, Control, and Loss Reduction Techniques

Category

Ensuring Quality and Reducing Losses: Rice Harvesting and Storage Techniques in China

Contributor

Ensuring Quality and Reducing Losses: Rice Harvesting and Storage Techniques in China

Country

Technical Solution