Effective storage methods are crucial for maintaining corn quality and reducing post-harvest losses. Proper moisture reduction and impurity removal help prevent spoilage and ensure safe storage. Professor Zhang Yurong from the College of Grain and Strategic Reserves at Henan University of Technology introduces common storage methods for corn ears and kernels, key drying techniques, and practices for impurity elimination.

Before storage, corn ears must be husked and sorted, while kernel storage requires wind-sifting and screening to remove impurities and keep impurity content below 1%. Moisture reduction methods include sun-drying, natural ventilation, or mechanical drying, with continuous monitoring to ensure optimal storage conditions.

1. Importance of Moisture Reduction and Impurity Removal

Upon harvest, corn typically exhibits a relatively high moisture content and inevitably becomes intermingled with corn husks, soil, and other impurities. To ensure the safety and minimize losses during storage, it is imperative to reduce moisture content and eliminate impurities prior to storage.

2. Corn Storage Methods

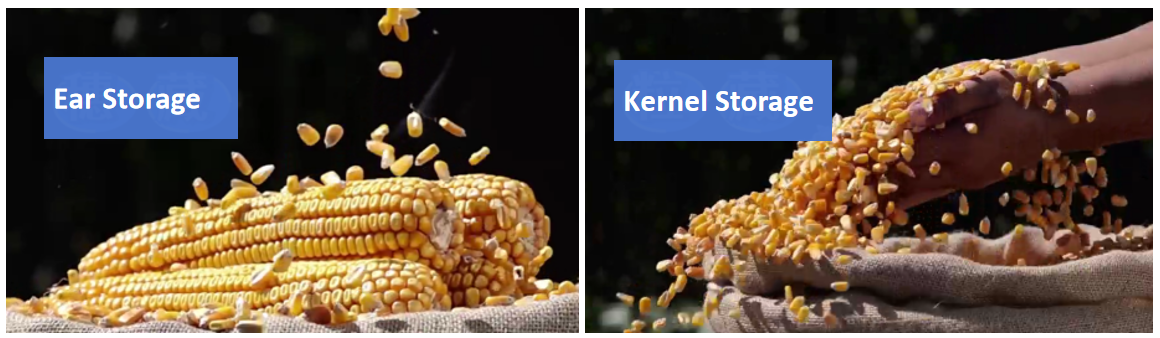

Corn storage methods primarily include ear storage and kernel storage.

2.1 Ear Storage

For ear storage, the common post-harvest practices involve either sun-drying or utilizing ventilated drying facilities to reduce moisture levels.

In the eastern part of Inner Mongolia and the three northeastern provinces of China, if conditions allow for sun-drying, the relatively warm weather after harvest can be utilized to spread out the corn ears on sun-facing ground for drying and moisture reduction. Once the corn ears are completely dry, they are loaded into storage equipment for winter storage. At this stage, the safety of the stored corn ears is relatively high. For farmers without sun-drying conditions, high-moisture corn ears can be directly loaded into a naturally ventilated drying warehouse, using winter’s low temperatures, wind, and solar energy for drying and moisture reduction.

2.2 Impurity Removal for Ear Storage

Before storage, corn ears must have their husks completely removed, with green or moldy ears sorted out, and any mixed corn silks, soil, or other impurities eliminated to prevent the corn ears from heating up and developing mold during storage, which could lead to losses.

2.3 Kernel Storage

2.3.1 Drying Methods for Corn Kernels

In addition, for kernel storage, depending on the actual conditions, sun-drying or using a corn wind-drying warehouse with natural ventilation for moisture reduction can be adopted. Small continuous dryers or re-circulating batch dryers may also be used for moisture reduction.

When sun-drying corn kernels for moisture reduction, it is important to determine the average thickness of the corn layer based on sunlight, temperature, wind, the moisture content of the corn, and the conditions of the drying field. The corn should then be arranged in alignment with the direction of sunlight or wind and turned at appropriate intervals.

2.3.2 Moisture Content Monitoring

During the moisture reduction process, the moisture content of the corn must be measured continuously to ensure that the kernels are adequately dry. A common method is to judge by touch and by biting the kernels. If the kernels feel smooth, flow freely, and produce a crisp sound, it indicates that the corn is sufficiently dry. If conditions permit, a portable rapid moisture meter can also be used to measure the moisture content.

2.3.3 Impurity Removal for Kernel Storage

For impurity removal before storing corn kernels, impurities are inevitably mixed in during threshing, sun-drying, and other processes, posing a threat to the safety of subsequent storage. Therefore, before storage, corn kernels must be thoroughly cleaned. Specifically, a wind-sifting and screening method can be employed to remove dust, stones, and other impurities to the greatest extent possible. Additionally, diseased, shriveled kernels and pests should be removed to ensure that the stored corn is dry, plump, and clean, with the impurity content controlled to within 1%.

The mastery of high-moisture corn post-harvest processing technology is critical for farmers to reduce post-harvest losses, optimize grain quality and ultimately enhance economic returns and food security by minimizing waste and improving market competitiveness.

Reference:

The Expert Talk video series produced by the National Food and Strategic Reserves Administration of China

Related Links:

1. Corn Storage Equipment Types and Applicability

2. Wheat Mold Prevention, Control, and Loss Reduction Techniques

3. Corn Storage in Open-air Structures: Common Methods, Technical Requirements, and Considerations

4. Standards for Grain Conservation and Loss Reduction Across Different Circulation Stages

5. Innovation-driven Approaches to Post-harvest Grain Conservation and Loss Reduction

6. Ensuring Quality and Reducing Losses: Rice Harvesting and Storage Techniques in China

Category

Technical Solution

Contributor

High-Moisture Corn Post-harvest Processing: Integrated Strategies for Moisture Control and Impurity Removal

Country

Technical Solution