Wheat mold not only diminishes the grain’s processing quality but also poses potential health risks to both humans and animals. In this article, Sun Changpo, Chief Engineer of the Standards and Quality Center at the National Food and Strategic Reserves Administration (the Administration), provides expert insight into the causes and consequences of wheat mold, effective prevention strategies during harvest, national grain conservation efforts, and future directions for ensuring grain safety.

1. Understanding Wheat Mold: Causes and Impacts

1.1 Key factors affecting mold development

Research indicates that temperature and moisture are the primary factors driving the development of mold in wheat. The safe storage duration for wheat decreases as temperature and moisture content rise. Wheat mold not only reduces the grain’s processing value but may also pose risks to human and animal health.

1.2 Harvest-time vulnerabilities

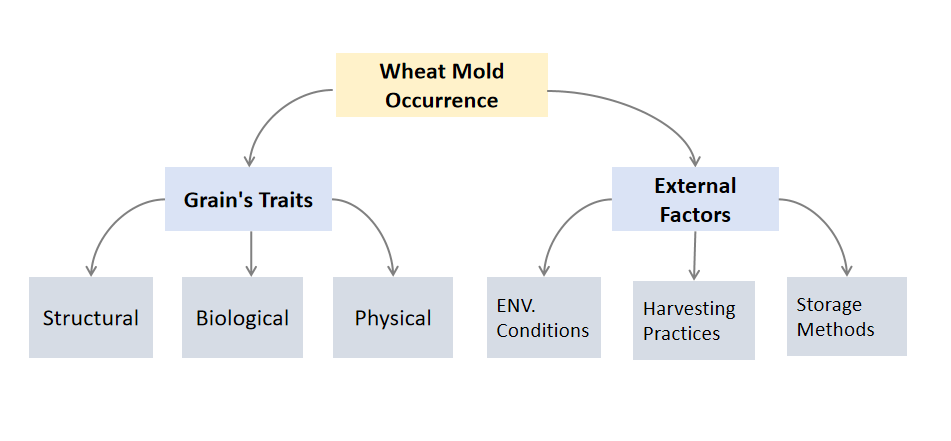

During the harvest season, the occurrence of wheat mold is closely associated with the grain’s structural, biological, and physical traits, as well as environmental conditions, harvesting practices, and storage methods.

On one hand, newly harvested wheat undergoes a physiological after-ripening period that typically lasts about two months. During this time, wheat experiences high respiration rates and intense metabolic activity, which result in the release of considerable moisture and heat. These conditions can lead to the formation of localized areas with high temperature and humidity. Moreover, wheat grains possess thin outer layers, soft tissues, and a high content of hydrophilic substances, making them highly susceptible to moisture absorption.

On the other hand, improper post-harvest handling, combined with excessive temperature and humidity during storage, significantly increases the risk of mold development. Furthermore, adverse weather conditions during harvest, such as rainfall or high temperatures, create favorable environments for localized fungal growth, which can easily lead to mold contamination.

2. Effective Prevention During Wheat Harvest

2.1 Optimal timing for harvest

First, farmers should seize the appropriate agricultural timing for harvest. As the saying goes, "Harvest at 90% maturity for 100% yield; harvest at 100% maturity and lose 10%." The end of the waxy ripeness stage is the optimal period to harvest wheat, featuring high yield and good quality. Harvesting too early or too late reduces both yield and grain quality. During the harvest season, farmers should monitor weather conditions closely and plan harvesting activities accordingly. Adverse weather conditions, such as strong winds, continuous rainfall, or high temperatures, can cause wheat to lodge, absorb water, germinate, or develop mold.

2.2 Ventilation and drying techniques

Second, proper ventilation and drying are essential to reduce moisture. Following harvest, farmers should make full use of hot, dry summer weather to sun-dry wheat on cement floors or rooftops. Alternatively, wheat can be transported to post-harvest service centers for drying and processing, ensuring timely ventilation and moisture reduction.

Meanwhile, newly harvested grain often contains impurities such as straw, dust, and broken kernels, which can lead to insect infestation in grain piles and mold growth, affecting storage stability. These impurities should be effectively removed using manual sorting or mechanical methods such as winnowing.

2.3 Scientific storage methods

Third, farmers should value grain conservation and employ scientific storage methods. Farm households typically have relatively simple grain storage facilities, relatively outdated storage technologies, and poor resistance to grain mold, making losses more likely. Therefore, farmers are advised to improve their awareness of scientific grain storage methods.

Once properly cleaned and dried, wheat should be stored promptly using the “heat-sealed storage” method, which is a traditional storage method that utilizes high temperatures to eliminate surface insects and microorganisms, preventing grain from absorbing moisture and developing pests or mold. Storage containers should be moisture-proof, pest-resistant, corrosion-resistant, appropriately sized, and designed for easy loading and unloading. Additionally, regular inspections of stored grain should be conducted to ensure safe storage.

3. National Initiatives for Grain Conservation

3.1 Strengthening guidance on scientific grain storage

In recent years, the National Food and Strategic Reserves Administration has promoted the adoption of scientific grain storage technologies among farmers. By leveraging promotional campaigns, demonstration projects, and targeted investment support, the Administration has distributed 10 million sets of scientific grain storage equipment to farmers nationwide. It has also guided local departments to implement measures to strengthen promotion and guidance on scientific grain storage techniques for farmers and encourage them to build "scientific grain storage facilities" in the fields or near their homes, helping to prevent grain mold formation and effectively solve their post-harvest concerns.

Grain storage

3.2 Optimizing post-harvest services

Relevant government departments have established over 5,500 post-harvest grain service centers nationwide and guided local authorities in strengthening their daily management and operations. These centers provide timely services such as grain cleaning, drying, and other services to farmers, helping them to improve grain quality and reduce post-harvest losses.

3.3 Innovating and optimizing service delivery

The Administration guides local authorities and relevant enterprises to continuously optimize five service areas: on-site services, consultation services, appointment services, information services, and post-harvest services. It further explores and promotes grain appointment purchasing systems, helping farmers to reduce travel, avoid long queues, and accelerate grain sales.

In addition, it enhances coordination with meteorological and relevant departments to closely monitor weather conditions, provide weather advisory services, and timely optimize and adjust procurement arrangements as needed. These efforts ensure that farmers can sell their grain efficiently and that harvested grain is promptly and properly stored in full.

3.4 Reinforcing technical standards

Currently, the Administration has promoted the publication of 19 standards related to mycotoxin detection methods, and is further improving and perfecting relevant standard systems to provide technical support for ensuring grain quality and safety.

In addition, the newly-released technical specifications for small-scale farm grain storage facilities define key aspects such as their classifications, equipment models, and technical requirements. These specifications serve as practical guidelines for farmers to build new grain storage facilities or renovate existing ones, thereby to help improve their grain storage capabilities and storage conditions.

Grain storage

4. Future Directions for Grain Safety

Food security remains a long-term priority. Looking ahead, the Administration will continue to

(1) promote training and services focused on scientific grain storage techniques for farmers and encourage qualified operational entities to provide grain storage services for farmers, helping them reduce storage loss rates and increase income.

(2) strengthen operational oversight of post-harvest grain service centers, enhance their functional capacity, and guide local authorities in accelerating the development of on-site grain drying capacities.

(3) refine and update grain standards to provide important technical support for ensuring grain quality and safety.

Reference:

The Expert Talk video series produced by the National Food and Strategic Reserves Administration of China

Wheat Mold Prevention, Control, and Loss Reduction Techniques

Related Links:

1. Corn Storage Equipment Types and Applicability

3. Corn Storage in Open-air Structures: Common Methods, Technical Requirements, and Considerations

4. Standards for Grain Conservation and Loss Reduction Across Different Circulation Stages

5. Innovation-driven Approaches to Post-harvest Grain Conservation and Loss Reduction

6. Ensuring Quality and Reducing Losses: Rice Harvesting and Storage Techniques in China

Category

Wheat Mold Prevention, Control, and Loss Reduction Techniques

Contributor

Wheat Mold Prevention, Control, and Loss Reduction Techniques

Country

Technical Solution